A waste heat boiler is a device used to recover high-temperature waste heat generated in high-temperature industrial kiln systems. During the operation of the cement kiln, high-temperature gases pass through the kiln. These high-temperature gases can be used to generate steam or hot water for power generation or heating for other processes. Due to the characteristics of high-temperature gas, waste heat boilers need to use materials that can withstand relatively high temperatures. These materials are often called high-temperature refractory materials. What are the refractory materials used for lining waste heat boilers? refractory for waste heat boiler castable refractory, castable insulation. Is it appropriate to use refractory castables as lining materials for waste heat boilers?

Refractory Materials for Waste Heat Power Generation

Waste heat power generation mainly uses various wear-resistant amorphous refractory materials. For example, the elbow part of the waste heat power generation and grate cooler uses high-strength wear-resistant castables, the pipe part uses wear-resistant plastic mash materials fixed with tortoise shell mesh, and the settling chamber uses mash materials and other refractory products.

Working principle of waste heat boiler. After burning fuel, gas, and coal, high-temperature flue gas is released to release heat, and the high-temperature flue gas enters the furnace. Then it enters the waste heat recovery device of the front smoke box, then enters the smoke pipe, and finally enters the waste heat recovery device of the rear smoke box flue. The high-temperature flue gas turns into low-temperature flue gas and is discharged into the atmosphere through the chimney. Since waste heat boilers greatly improve the utilization of heat released by fuel combustion, this type of boiler is very energy-saving.

Waste heat boiler series refractory castables are mixed powder granular materials composed of a variety of aggregates or aggregates and one or more binders. When used, it is mixed evenly with one or more liquids and has strong fluidity and plasticity. Refractory castables for waste heat boilers usually use unshaped refractory materials such as high-strength wear-resistant, self-flowing corundum products, lightweight insulation, and thermal shock-resistant products.

Corundum self-flowing castable. Artesian products have good fluidity, reasonable solidification time, labor saving, fast and convenient. High strength, long service life, good thermal insulation performance, high temperature resistance, good thermal shock stability, corrosion resistance and erosion resistance. It can be pumped for mechanized construction, shorten the furnace building time, bake quickly, and shorten the baking time. It is a substitute for low-cement, ultra-low cement, and cement-free castables. It is especially used for thin-walled linings such as heating furnace roofs, furnace walls, water-cooling pipe wrapping systems, and hot repairs of various kilns.

Lightweight thermal insulation castable. Lightweight insulation products are composed of high-strength materials and ultra-fine powder composite additives. This product has the characteristics of light volume, high compressive strength, acid and acid gas corrosion resistance, heat insulation, low water absorption, and simple construction. It is an ideal product for construction of high temperature and alkali corrosion resistant parts. Lightweight insulation castables have the characteristics of bulk density, low thermal conductivity, light weight, high compressive strength, acid and acid gas corrosion resistance, etc., which can reduce the heat energy consumption and furnace lining weight of industrial kilns.

High strength and wear-resistant castable. It has strong impact resistance, compressive strength and good construction workability. A certain thickness of wear-resistant layer is formed on the surface of the warehouse or mine tank through manual plastering, which can meet the technical requirements after normal maintenance. High wear resistance and good durability. long lasting.

Steel fiber high-strength refractory castable. It is made of bauxite clinker as aggregate, bauxite clinker and corundum fine powder as matrix, ultrafine powder and other composite materials as binders and additives, and stainless steel heat-resistant fibers. In addition to traditional high-temperature wear resistance, the product also adds a certain amount of heat-resistant stainless steel fiber. It prevents the damage to the furnace wall caused by the difference between the aggregate and the matrix in the material at high temperatures, as well as the stress caused by the temperature gradient change when starting and stopping the furnace. At the same time, due to the addition of steel fibers, the overall strength of the waste heat boiler is greatly improved.

To summarize, refractory castable (also known as refractory castable or refractory concrete) is a specialized material used to repair or construct high-temperature industrial equipment. These materials are usually a mixture of refractory aggregate and refractory cement used to form a refractory lining or coating. Refractory castables have good high-temperature resistance, wear resistance and corrosion resistance and are therefore widely used in many high temperature industrial applications.

High-temperature refractory materials are usually made of refractory bricks or refractory castables. These materials can withstand high temperatures and chemical attack to ensure the safe operation and long-term stability of the boiler. Therefore, in order to ensure the performance and life of the waste heat boiler, high-temperature refractory materials are usually selected instead of castables to build the internal structure of the boiler.

Selection of Refractory Materials for Waste Heat Boiler Cooling Chamber Walls

In a waste heat boiler with a supplementary combustion device, the furnace wall near the burner is directly radiated by the flame or high-temperature flue gas, and the surface temperature of the furnace wall can reach about 1500°C. When there is a water-cooled wall tube inside the furnace wall, the temperature can generally reach about 1300°C, and when there is no water-cooled wall tube, the surface temperature of the furnace wall is generally below 1000°C. When the membrane water-cooled wall is arranged, the furnace wall surface temperature drops below 800°C. At this time, the metal temperature of the membrane fireplace wall does not exceed 450°C.

Judging from the current development trend of furnace wall structures, when the heat source temperature is above 900°C, membrane water-cooled walls can be preferred as the furnace wall to avoid the need for refractory lining in the cooling chamber. Only a light insulation layer and insulation materials are laid on the outside of the membrane water-cooled wall to form a light furnace wall structure, which has good sealing and insulation effects. Especially for waste heat sources, in order to improve the utilization quality of waste heat, it is necessary to reduce heat dissipation losses and reduce air leakage. Using this model of water-cooled wall structure can well achieve the purpose of waste heat utilization, especially in waste heat power generation applications. This requirement becomes higher. Reducing heat dissipation loss can increase waste heat utilization power and improve waste heat utilization efficiency.

When the flue gas temperature is lower than 450°C, the use of membrane water-cooled wall heating surfaces will cause an increase in steel consumption. At this time, because the heat source temperature is lower than the critical oxidation temperature of carbon steel, you can choose to use carbon steel plates as the inner furnace plates of the protective walls. The external application of thermal insulation materials will also provide good sealing and insulation functions.

When refractory materials need to be used for lining the cooling chamber, these requirements must be followed. For cooling chambers without water-cooled walls, when the temperature of the inner wall of the furnace wall is below 1300°C, clay refractory materials for boilers with an A1203 content of not less than 40% can be used to protect the vault and the fire wall where flue gas is directly washed away. The inner wall of the furnace wall with a wide-tube water-cooled wall can use general clay refractory materials with an A1203 content of less than 40% because of the cooling effect of the water-cooled wall tube on the flue gas. When there is a water-cooled wall composed of finned tubes, because the finned tubes have a good shielding effect on flue gas radiation, sintered clay water glass refractory concrete or sintered Portland cement refractory concrete can be used in the furnace wall where refractory materials are directly laid. When there is a membrane water-cooling wall, because the membrane water-cooling wall has a complete shielding effect on smoke radiation, it only needs to be laid directly on the membrane water-cooling wall with heat insulation materials and thermal insulation materials.

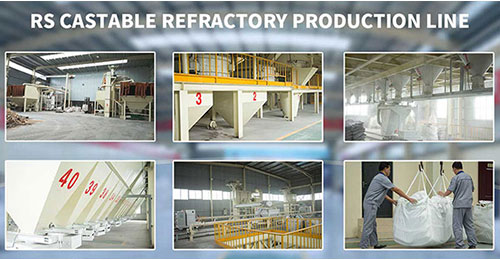

To purchase high-quality refractory furnace lining refractory products, please choose Rongsheng Refractory Materials Manufacturer. We can provide high-quality refractory for waste heat boiler castable refractory, castable insulation. And our comprehensive customer service also guarantees long-life refractory linings. Contact us to get free samples and quotes.