Among the refractory materials, silicon carbide raw material is also a very common refractory raw material. So, what is silicon carbide? What kind of properties does silicon carbide have and why can it be used in refractory raw materials? Are there other uses for silicon carbide? With full of doubts, I have a certain understanding of silicon carbide by consulting the information. It turns out that silicon carbide has a really wide range of uses. Contact Rongsheng for free quotes.

Get Free Quote

What is Silicon Carbide?

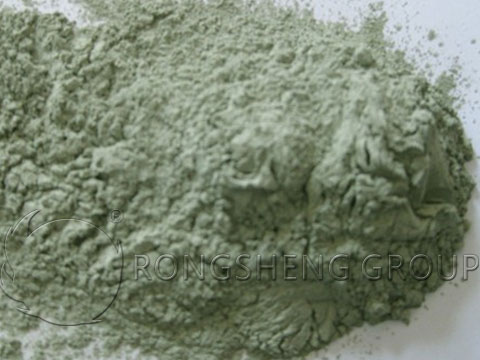

Silicon carbide is an inorganic substance with the chemical formula SiC. It is made from raw materials such as quartz sand, petroleum coke (or coal coke), wood chips (salt is required to produce green silicon carbide), and other raw materials through high-temperature smelting in a resistance furnace. Silicon carbide also exists in nature as a rare mineral, moissanite. Among the non-oxide high-tech refractory raw materials such as C, N, and B, silicon carbide is the most widely used and most economical one, which can be called gold steel sand or refractory sand.

Get Free Quote

The Quality of Silicon Carbide

Pure silicon carbide is colorless, and industrially produced brown to black is due to iron-containing impurities. The iridescent luster on the crystal is due to the protective layer of silica produced on its surface. Silicon carbide has two commonly used basic types, black silicon carbide, and green silicon carbide, both of which belong to α-SiC.

- ①Black silicon carbide contains about 95% SiC. Its toughness is higher than that of green silicon carbide, and it is mostly used to process materials with low tensile strength. Such as glass, ceramics, stone, refractory materials, cast iron, and non-ferrous metals.

- ②Green silicon carbide contains more than 97% SiC and has good self-sharpening. Most of them are used for machining cemented carbide, titanium alloy, and optical glass, and also for honing cylinder liners and fine grinding high-speed steel tools.

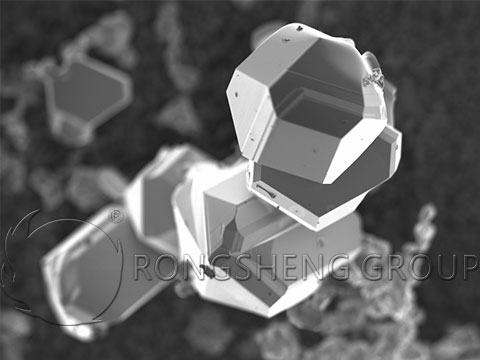

In addition, there is cubic silicon carbide, which is a yellow-green crystal obtained by a special process. The abrasive tool used for production is suitable for superfinishing of bearings. The surface roughness can be processed from Ra32~0.16 microns to Ra0.04~0.02 microns at one time.

Properties of Silicon Carbide

- Silicon carbide has at least 70 crystalline forms.

- Silicon carbide has stable chemical properties, high thermal conductivity, a small thermal expansion coefficient, and good wear resistance.

- Silicon carbide is very hard, with a Mohs scale of 9.5, second only to the world’s hardest diamond (grade 10).

- Silicon carbide has excellent thermal conductivity and is a semiconductor that resists oxidation at high temperatures.

- The specific gravity of silicon carbide is 3.20-3.25, and it has a high sublimation temperature, about 2700 °C.

Get Free Quote

Why Can Silicon Carbide be Used as a Raw Material for Refractory Materials?

Silicon carbide has stable chemical properties, high thermal conductivity, a small thermal expansion coefficient, and good wear resistance. At the same time, because of its specific gravity of 3.2g/cm3 and high sublimation temperature (about 2700 °C), silicon carbide is very suitable as a raw material for bearings or high-temperature furnaces. The advanced refractory material made of silicon carbide has the advantages of thermal shock resistance, small size, lightweight and high strength, and good energy-saving effect. It is widely used in various smelting furnace linings, high-temperature furnace components, silicon carbide plates, lining plates, supports, saggers, silicon carbide crucibles, etc.

Applications of Silicon Carbide

Silicon carbide has four main application areas, namely: functional ceramics, advanced refractories, abrasives, and metallurgical raw materials.

- (1) As an abrasive, it can be used to make abrasives, such as grinding wheels, oil stones, grinding heads, sand tiles, etc.

- (2) As metallurgical deoxidizer and high-temperature resistant material.

- (3) High-purity single crystals can be used to manufacture semiconductors and silicon carbide fibers.

The main use of silicon carbide. For 3-12 inch single crystal silicon, polycrystalline silicon, potassium arsenide, quartz crystal, and other wire cutting. Solar photovoltaic industry, semiconductor industry, piezoelectric crystal industry engineering processing materials.

For semiconductors, lightning rods, circuit components, high-temperature applications, UV detectors, and structural materials. Astro, disc brakes, clutches, diesel particulate filters, filament pyrometers, ceramic membranes. Cutting tools, heating elements, nuclear fuel. Jewelry, steel, protective gear, catalyst carrier, and other fields.

Silicon Carbide for a Wide Range of Applications

Silicon carbide has stable chemical properties, high thermal conductivity, a small thermal expansion coefficient, and good wear resistance. In addition to being used for abrasives, there are many other uses.

Abrasives

Mainly used to make a grinding wheel, sandpaper, abrasive belt, oil stone, grinding block, grinding head, and grinding paste. And the grinding and polishing of monocrystalline silicon, polycrystalline silicon, and piezoelectric crystals in the electronics industry in photovoltaic products.

chemical

It can be used as a raw material for the manufacture of silicon tetrachloride and is the main raw material for the silicone resin industry.

Refractory raw materials

The use of silicon carbide has the characteristics of corrosion resistance, high-temperature resistance, high strength, good thermal conductivity, and impact resistance.

- On the one hand, silicon carbide can be used in various smelting furnace linings, high-temperature furnace components, silicon carbide plates, linings, supports, saggars, silicon carbide crucibles, etc.

- On the other hand, it can be used for high-temperature indirect heating materials in the non-ferrous metal smelting industry. Such as vertical tank distillation furnace, rectification furnace tray, aluminum electrolytic cell, copper melting furnace lining, arc plate for zinc powder furnace, thermocouple protection tube, etc. It is used to make high-grade silicon carbide ceramic materials such as wear resistance, corrosion resistance, and high-temperature resistance.

non-ferrous metals

The use of silicon carbide has high-temperature resistance, high strength, good thermal conductivity, and impact resistance, and is used as high-temperature indirect heating material. Such as solid pot distillation furnace, rectification furnace tray, aluminum electrolytic cell, copper melting furnace lining, arc plate for zinc powder furnace, thermocouple protection tube, etc.

steel

Low-grade silicon carbide (containing about 85% SiC) is an excellent deoxidizer, which can speed up steelmaking, facilitate chemical composition control, and improve steel quality. It can be used as a deoxidizer for steelmaking and a modifier for cast iron structure. Silicon carbide deoxidizer is a new type of strong composite deoxidizer, which replaces the traditional silicon powder to deoxidize. Steelmaking efficiency, improving steel quality, reducing raw and auxiliary material consumption, reducing environmental pollution, improving working conditions, and improving the comprehensive economic benefits of electric furnaces are all of great value.

Using the characteristics of corrosion resistance, thermal shock resistance and wear resistance, and good thermal conductivity of silicon carbide, it is used in the lining of large blast furnaces to improve the service life.

Metallurgical beneficiation

The hardness of silicon carbide is second only to diamond, and it has strong wear resistance. It is an ideal material for wear-resistant pipes, impellers, pump chambers, cyclones, and hopper linings. In particular, the discharge pipelines used in mining processing plants are placed inside. Its wear resistance is 6-7 times that of ordinary wear-resistant materials.

Building materials ceramics

Using its thermal conductivity, thermal radiation, and high thermal intensity characteristics, manufacturing thin-plate kiln furniture. It can not only reduce the capacity of kiln furniture, but also improve the loading capacity and product quality of the kiln, shorten the production cycle, and is an ideal indirect material for ceramic glaze baking and sintering.

energy saving

With good thermal conductivity and thermal stability, it is used as a heat exchanger. Fuel consumption is reduced by 20%, fuel is saved by 35%, and productivity is increased by 20-30%.

semiconductor element

Silicon carbide has excellent thermal conductivity and is a semiconductor that resists oxidation at high temperatures. Due to its high thermal conductivity, high breakdown electric field strength and high maximum current density, many people try to use it to replace silicon in the application of semiconductor high-power components. So far, this idea is feasible. In addition, it has a strong coupling effect with microwave radiation, and all its high sublimation points make it practical for heating metals. Silicon carbide is also widely used to make silicon carbide rods for electric heating elements.

jewelry

Synthetic Moissanite is also known as synthetic moissanite and synthetic moissanite (chemical composition SiC). The dispersion is 0.104, which is larger than that of diamond (0.044). Refractive index 2.65-2.69 (diamond 2.42). It has the same diamond-like lustre as a diamond, with a stronger “fire” and is closer to a diamond than any imitation ever made.

other uses

It can also be used to make rocket nozzles, gas turbine blades, etc. In addition, its wear resistance is 5-20 times of the service life of cast iron rubber, and silicon carbide is also one of the ideal materials for solar water heaters for highways, aviation runways, etc.

Through the above content, we found that silicon carbide is really a widely used material. To learn more about Silicon Carbide, please contact us. We can provide free samples and quotations. We supply silicon carbide products to markets all over the world. For example, Japan, USA, Korea, Taiwan, Thailand, Singapore, India, Turkey, Mexico and Germany, etc. Our silicon carbide raw materials can be supplied in large quantities, and we have begun to expand the application of nano-scale silicon carbide powder with extremely high technical content.