In the configuration of high-temperature industrial furnace lining, not only castable integral furnace lining and refractory brick lining are needed, but also ceramic fiber cotton lining. They are used in different parts of the furnace lining according to the temperature conditions they can withstand. Rongsheng refractory material manufacturer has made a comparison between ceramic fiber insulation cotton and refractory bricks to help enterprises better choose material products suitable for high-temperature industrial furnace lining.

Materials

Ceramic cotton is made by melting high-purity clay clinker, alumina powder, silica powder, chrome sand and other raw materials at high temperature in an industrial electric furnace to form a fluid. Then it is blown by compressed air or spun into fibers by a spinning machine, and the cotton is collected by a cotton collector to form insulation cotton.

Refractory bricks are referred to as fire bricks. They are refractory materials made by burning refractory clay or other refractory raw materials. They are light yellow or brown. According to the different components of refractory bricks, they can be divided into five categories, namely: silicon-aluminum refractory bricks, alkaline series refractory bricks, carbon-containing refractory bricks, zirconium-containing refractory bricks, and insulating refractory bricks.

Weight

The weight of ceramic fiber insulation cotton is relatively small compared to the density of refractory bricks, so it is lighter, occupies less space, has good flexibility, and has a lighter burden on equipment. Insulation cotton is about one-tenth the weight of refractory bricks.

Construction

- Ceramic fiber insulation cotton is accurate in size, easy to cut and install, easy to construct, saves labor hours, does not expand when heated, simple to maintain later, and has a long service life.

- Refractory bricks are often produced in batches, with high prices, long installation cycles, and high construction costs. Moreover, brick joints in masonry cannot be avoided. After thermal expansion and contraction, the brick joints are stretched open, and they are easy to break and fall off later, and are not easy to repair.

Energy saving and environmental protection

- Insulation cotton has low thermal conductivity, excellent wind erosion resistance and mechanical impact resistance. It can accept sudden heating and cooling inside industrial kilns or other high-temperature facilities, with low fuel consumption, and is more energy-saving and environmentally friendly.

- Traditional refractory bricks need to be heated up slowly in the early stage and cooled down slowly after use to avoid high fuel consumption of refractory bricks.

Industrial Furnace Insulation Cotton Ceramic Fiber Insulation Cotton

Ceramic fiber insulation cotton is produced by melting the raw materials at high temperature in a resistance furnace and blowing/spinning into fibers. Ceramic fiber is a neutral and acidic material. Except for reacting with strong acids and alkalis, it is not corroded by other weak bases, weak acids, water, oil, and steam. It does not infiltrate lead, aluminum, and copper, and has excellent flexibility and elasticity.

Ceramic fiber has a small density, which is more than 75% lighter than the lightweight insulation brick lining and 90%-95% lighter than the lightweight castable lining. The thermal conductivity is about 1/8 of that of lightweight clay bricks and 1/10 of that of lightweight heat-resistant linings (castables). The heat capacity is only about 1/10 of that of lightweight insulation linings and lightweight castable linings. It greatly reduces energy loss and has significant energy-saving and heat storage effects.

At the same time, ceramic fiber has the characteristics of simple construction, no need for furnace baking, shortened construction period, and easy installation. Ceramic cotton has the characteristics of stable performance, long fiber, high tensile strength, less slag balls, high thermal stability, white color, etc. The classification temperature is 1050-1400℃. It is a material for producing fiber textiles and an ideal material for sealing, filling and insulation in high temperature environments.

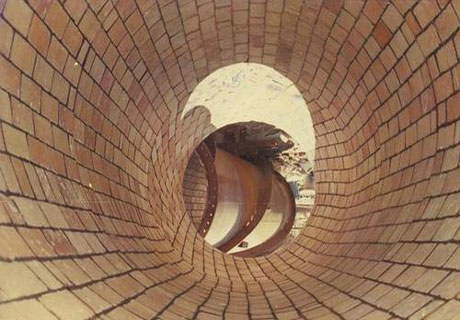

On the Spraying and Slinging Processes of Ceramic Fibers

There are two processes for producing ceramic fibers, namely the spraying process and the spinning process. What is the difference between these two processes and what is the development trend?

From the production history, the earliest one was the spraying production process. However, the production capacity of a single line is relatively low, and the annual output is generally 1,000 to 1,500 tons. In order to improve production efficiency, new ceramic fiber production processes have been continuously explored and researched, and a more advanced spinning production process was invented. The production capacity of a single production line of the spinning process is 2 to 4 times that of the spinning process. The annual output of a single line of the spinning process is nearly 6,000 tons.

Application. The spinning process of ceramic fiber cotton has been recognized by most industry manufacturers and customers. Almost all new ceramic fiber production lines in China in the past 10 years have adopted the spinning process. Blown ceramic fiber cotton also has its unique application, such as the need to break the fiber into secondary processed products (such as making vacuum formed products, etc.). Blown fiber is more popular because the fiber is thinner and easier to fully mix with other raw materials.

Trend. The ceramic fibers of spinning and spinning processes have their own strengths. Customers should take their strengths and avoid their weaknesses according to actual applications in order to achieve better results. Of course, the application occasions of spinning blankets are far more than those of spinning blankets.

In terms of development prospects, the total domestic ceramic fiber production will increase, and new production lines will still be dominated by spinning production processes. Relatively speaking, the production scale of blowing ceramic cotton and the proportion of the total market will gradually decrease. The spinning cotton production process is more suitable for enterprises with smaller production scales, especially those with smaller early investment. The market competition for spinning production technology in China will also become more and more fierce, which is definitely a good thing for consumers. Because you can spend less money and enjoy more and better products. This is definitely a good thing for the development of related industries in China’s thermal energy application, especially for energy conservation and consumption reduction in industrial production processes.