High-temperature resistant aluminum silicate board, ceramic fiber insulation board, high density, fireproof, airtight, stable quality. How to judge the thermal insulation performance of Ceramic Fiber Boards? The main purpose of heat preservation is to reduce the heat loss of heat medium during transportation, save fuel, and ensure the temperature inside the high-temperature kiln. Insulation materials can be divided into coating type, winding type, filling type, pouring type, spraying type, etc. according to different performances and construction methods. A ceramic fiber insulation board is a lightweight refractory insulation material that has emerged in the past ten years.

Aluminum silicate felt, high-temperature resistant aluminum silicate fiber board, ceramic fiber insulation board. To judge the thermal insulation performance of ceramic fiber boards, we should start from the following aspects.

- Thermal conductivity is a parameter of the heat transfer ability of the ceramic fiberboard. It reflects the thermal conductivity of the material and is the main thermophysical property of the insulation material. The thermal conductivity of ceramic fiber insulation board at 600° is only 0.145W/(M.K).

- Bulk density. Each insulation material has a reasonable bulk density, within this range the thermal conductivity is small and the insulation effect is better. In order to save energy and reduce the load of the insulation structure in the project, insulation materials with low volume density should be used as much as possible. The bulk density of ceramic board insulation is 280kg/m3, which is 1/4 of that of light refractory materials. This is a great insulation material.

- Operating temperature refers to the limited temperature that insulating materials can withstand for long-term safe and reliable operation. The long-term use temperature of high temperature ceramic insulation board is between 850 and 1300 degrees, and it is a high-temperature-resistant product except for mullite fiber.

- Compressive strength. Ceramic fiber insulation board is a semi-rigid insulation material that will not fail when subjected to compressive loads.

- Linear expansion coefficient. If the coefficient of linear expansion of the thermal insulation material is large, the interior will be deformed and generate large stress after being heated, destroying the thermal insulation structure. Unlike conventional insulation materials, ceramic fiberboard does not expand when heated. There is no need to reserve expansion joints during use, and they can be squeezed tightly during installation.

- Chemical properties. Different use environments require thermal insulation materials to have good chemical stability. Acid and alkali resistance, corrosion resistance, and oxidation resistance, ceramic fiberboard performs very well in these aspects.

Applications and Advantages of Ceramic Fiber Boards

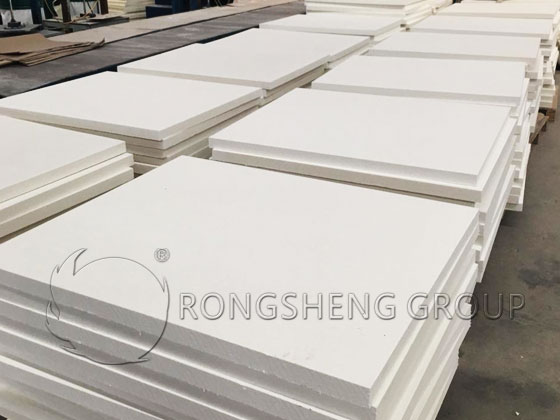

Ceramic fiberboard is widely praised and used as a refractory insulation material. It has many advantages, such as light bulk density, good thermal stability, high-temperature resistance, low thermal conductivity, good elasticity, sound insulation, mechanical vibration resistance, electrical insulation, and good chemical stability. Ceramic fiber aluminum silicate board, plate shape, environmental protection, and high-temperature resistance, complete specifications.

Wet-laid ceramic fiber insulation board is made of ceramic fiber loose cotton through a wet vacuum forming process. The process is a bit complicated, so the price is a bit expensive. The finished product is mainly used for high-temperature insulation projects. Ceramic fiber board, kiln heat insulation, and sealing wet-process high-aluminum mechanism fire block. Next, let’s take a look at the application and advantages of ceramic board insulation.

Application of Ceramic Fiber Boards

- Ceramic fiber board is suitable for door seals and door curtains of various heat-insulating industrial kilns.

- Casing and expansion joints for high-temperature flue and air duct.

- High-temperature insulation and heat preservation of petrochemical equipment, containers, and pipelines.

- Protective clothing, gloves, hoods, helmets, and boots for high-temperature environments.

- Automotive engine heat shields, heavy oil engine exhaust pipe components, high-speed racing car composite brake friction linings.

- Sealing packing and gaskets for pumps, compressors, and valves used to transport high-temperature liquids and gases.

- Ceramic fiber products can be used for the insulation of high-temperature electrical appliances.

- Fire-fighting joint products such as fire doors, fire curtains, fire blankets, spark connection pads, and heat shields.

- Ceramic fiber products are suitable for heat insulation, thermal insulation materials, and brake friction pads used in the aerospace industry.

- Insulation and packaging of cryogenic equipment, containers, and pipelines.

- Ceramic fiber boards can be used as heat insulation, fire barriers, and automatic fire screens in important places, such as archives, vaults, and office building safes.

Advantages of Ceramic Fiber Boards

Compared with ceramic fiber blankets, ceramic fiber boards are hard and durable, with high density, high strength, and resistance to airflow erosion. The fibers on the surface are not easy to peel off and can be directly in contact with the flame. It can be used in places where fiber blankets are not suitable, such as flame baffles and kiln temperature zones. Aluminum silicate board High density, high temperature resistant ceramic fiber aluminum silicate insulation board.

Compared with refractory bricks, its outstanding feature is lightweight, which is only 1/4 of refractory bricks, which effectively reduces the burden on the load-bearing furnace body. In addition, traditional refractory bricks have poor resistance to rapid cooling and heating and are prone to cracking. This does not exist for high-temperature ceramic insulation board with excellent thermal stability.

In addition to the excellent performance corresponding to loose ceramic fiber cotton, it also has a hard texture, excellent toughness and strength, and excellent wind erosion resistance. It is an ideal energy-saving material for heat preservation of kilns, pipelines, and other equipment. It does not expand when heated, is light in weight, is easy to construct, and can be cut and bent at will.

A ceramic fiber board is a board made of refractory material. Maintains good mechanical strength even after heating. Compared with fiber blankets and felts, this product is a fiber insulation product with rigidity and supporting strength. Thermal insulation aluminum silicate fiber board, sound insulation, and fireproof ceramic fiber backing board.

Advantages of Dry-laid Ceramic Fiber Boards

The big difference between dry-process ceramic fiber insulation board and wet-process ceramic board insulation is that the bulk density of the dry process is light! In addition to light bulk density, dry-laid high temperature ceramic insulation board is an environmentally friendly inorganic material, which not only has a good sound insulation effect on sound but also has high-temperature resistance (Class A fire protection) and good waterproof performance. The ceramic fiberboard can also shrink arbitrarily and has good wind resistance and compression resistance. Aluminum silicate board, Sierra board, and ceramic fiber board for furnace wall lining insulation. Moreover, it is light in weight, convenient for transportation and construction, and has strong adhesion, which greatly improves construction efficiency.

There are many specifications of ceramic fiber insulation board, which can be cut to the corresponding size according to the requirements of customers. There are also many kinds of bulk density, the commonly used thickness is 50mm and 100mm, of course, there are other thicknesses. Rongsheng manufacturers can provide custom shapes and sizes of ceramic fiberboard. Feel free to get the ceramic fiber board price, by email, or leave us a message below.