In steel rolling equipment, the heating furnace is a very important heating equipment. Plastic refractory for boiler. The quality of the heating furnace will have a great impact on the quantity and quality of steel rolling, and the refractory materials used in the heating furnace will largely affect the use of the heating furnace.

Refractory materials can increase the service life of the heating furnace and can withstand slag erosion, air flow scouring, rapid heating, rapid cooling, high temperature, etc. With the continuous development of science and technology, many new materials have emerged one after another, and refractory materials are constantly being updated. However, no matter how the material changes, the performance of the heating furnace must be guaranteed to extend the service life of the heating furnace. Plastic refractory for a boiler. Let us understand together the advantages of refractory plastic materials of Rongsheng Refractory Material Manufacturer and their application in the top of the heating furnace.

Advantages of Using Refractory Plastics on the Roof of a Heating Furnace

The roof of a heating furnace is the location with the most severe airflow impact and the highest temperature. Whether it is the soaking section, heating section or preheating section, the refractory materials used have certain defects.

The performance of refractory bricks hanging on the roof is relatively poor, and the high temperature resistance is low. It is easy to cause local brick falling, and the service life is difficult to reach one year. The brick surface of the refractory brick hanging on the roof is uneven, and the sealing performance is poor, which increases the resistance to airflow, which is very unfavorable for heat radiation. There is a large heat loss and the heat utilization efficiency is relatively low.

At present, refractory castables or refractory plastics are usually used on the roof of a heating furnace. Although refractory castables make up for many defects of refractory bricks, castables still have very serious defects. Its earthquake resistance and heat resistance are very poor, and the erosion in the heating furnace is very serious. In particular, it sometimes causes large-area layered collapse of the roof of the heating furnace. There are two main reasons:

- First, because the pouring method is horizontal layer pouring, sometimes the pouring interval is too long due to the failure of the construction equipment, resulting in layer gaps.

- Second, the castable’s own resistance to rapid heating and cooling is worse than that of clay bricks, and its own thermal shock resistance is also relatively poor. Compared with castables, plastic has very good thermal shock resistance, which makes up for the defects of castables, which is also the main reason for its wide application.

Precautions for the Application of Refractory Plastics on the Roof of Heating Furnaces

Precautions for the construction of refractory plastics on the roof of heating furnaces

(1) Prevent watering

After tamping the plastics, do not let them get wet until they are baked. This is because plastics will soften and flow when they come into contact with water, leading to collapse.

(2) The expansion joints and surface treatment of plastics must be done well

Plastics are a refractory material with very large shrinkage. In order to allow it to crack in a man-made form when it shrinks, after the plastics are demolded, a 30mm to 50mm deep expansion joint line with a thickness of 1.5mm to 2mm needs to be cut on the surface every 1.5m with an expansion joint knife. That is, the expansion joints are cut in advance. When the plastic shrinks, it will crack in the pre-cut expansion joints, thus forming regular cracks.

After the plastics are demolded, the surface should also be shaved and pierced with air holes, with the air holes spaced approximately 150mm apart. In addition, in order to prevent irregular falling off around the anchor brick, the bottom surface of the anchor brick should be trimmed and tilted at a 45° angle after the mold is removed.

(3) The bonding between the anchor brick and the refractory plastic must be tight

The furnace roof plastic must be fixed on the furnace roof through the anchor brick. The tightness of the anchor brick and the refractory plastic will have a direct impact on the construction quality of the plastic furnace roof. plastic refractory for a boiler. Therefore, the tamping of the plastic anchor position is very important. In order to make the plastic and the anchor brick more closely contact, some wooden molds should be made in advance according to the shape of the anchor brick. When constructing the plastic, use the wooden mold to make a mold in the plastic at the anchor brick position. Then embed the anchor brick in the mold and use the pneumatic hammer to gently knock the anchor brick so that it can be in closer contact with the plastic. But be careful not to damage the anchor brick.

(4) Proper storage and preservation of fire-resistant plastics

The outer packaging of fire-resistant plastics must not be damaged before construction, because fire-resistant plastics are air-hardening materials. If the packaging is damaged, it will dry and harden. Therefore, it is necessary to pay attention to the storage and preservation of plastics, especially to protect the outer packaging of plastics.

Use different types of plastics at different positions on top of the heating furnace

The temperature difference between the soaking section, heating section, and preheating section of the heating furnace varies greatly, and the functions of each position are also different. When selecting plastics, not only the performance of plastics should be considered. At the same time, price factors and whether the material is suitable for construction should also be considered

Refractory plastics can be mixed with water, plasticizers, binders, plastic clay, powders and refractory aggregates and other raw materials, with a scientific particle size ratio. Compared with other materials, it is very suitable to use plastics at positions with large temperature changes. Because of its good stability, it will definitely replace some refractory materials and refractory bricks in the future, not only on the top and wall of the furnace, but also in other positions. plastic refractory for boiler. From another perspective, the use of plastics instead of the firing process of refractory bricks has saved social resources. It can not only improve social benefits, but also increase the economic benefits of enterprises. With the continuous improvement of the performance of plastics, many thermal equipment will definitely use new materials such as plastics in the future.

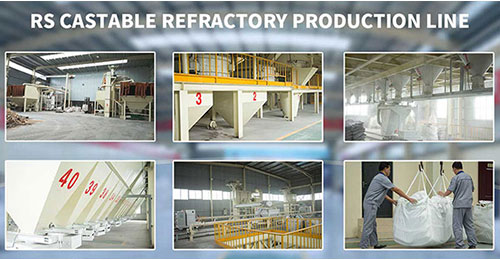

Rongsheng refractory manufacturer, environmentally friendly fully automatic monolithic refractory production line, specializes in providing high-quality monolithic refractory products for high-temperature industrial furnaces, providing favorable protection for the overall furnace lining, and effectively extending the service life of the high-temperature furnace lining. To purchase high-quality refractory plastic for heating furnace top, plastic refractory for boiler, please contact Rongsheng. Rongsheng manufacturer, provides free samples and quotations, as well as solutions for high-temperature industrial furnace linings.