Phosphorus impregnation of high-alumina bricks refers to placing fired high-alumina bricks in a container and impregnating them with phosphoric acid for more than two hours. After low-temperature treatment, their physical properties are significantly improved, making them suitable for use in harsh industrial furnace linings.

Indicators of High-Alumina Bricks After Phosphating

According to actual tests, after phosphate dilution, the softening temperature under load of ordinary high-alumina bricks increases by more than 30℃, the porosity decreases significantly by about 10%, and the bulk density increases by 0.2 g/cm³. Simultaneously, the flexural strength of phosphate-diluted high-alumina bricks decreases by 1%, showing a clear improvement in these indicators.

Phosphating not only improves the physical properties of high-alumina bricks but also improves their surface micro-textures and internal structure, resulting in neutral product performance and resistance to acidic and partially alkaline atmospheres.

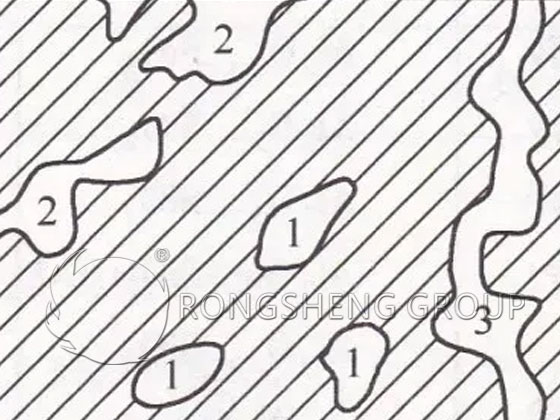

After high-alumina bricks are soaked in a phosphoric acid solution for a suitable time and temperature, the phosphoric acid solution penetrates into the pores of the brick, filling some of the pores. It also forms a micro-crack buffer structure, resisting erosion from rapid temperature changes. Furthermore, it reduces peeling and cracking under thermal stress impact.

Phosphating Treatment of High-Alumina Bricks

Phosphating ordinary high-alumina bricks is difficult because the phosphated product initially has a certain stickiness. Without specialized equipment, the phosphoric acid solution is everywhere, and improper handling can even cause the solution to adhere to the product during production.

Currently, some manufacturers of phosphated high-alumina bricks use specially welded containers to weigh each brick. The entire tray of bricks is placed in the container, allowing it to be thoroughly immersed in the phosphoric acid solution. This process helps heal minor surface cracks and makes the internal structure denser. After being left to stand for 24-48 hours, followed by low-temperature baking, its properties are enhanced, improving its wear resistance, impermeability, and corrosion resistance.

Other manufacturers have specialized phosphated equipment. Each high-alumina brick is phosphated and then individually heated and baked at a low temperature. This specialized phosphated equipment is convenient to use, but its performance is more stable and the results are better.

Differences between Low-Creep High-Alumina Bricks and Low-Porosity High-Alumina Bricks

Product Positioning

Both are high-alumina refractory bricks, made from high-quality high-alumina bauxite as the base material, produced through high-pressure molding and high-temperature firing. Due to differences in service environments, they utilize different auxiliary materials and process controls, forming two technical routes: “low-porosity” and “low-creep,” to meet the specific needs of different parts of the furnace lining for erosion resistance or creep resistance.

Low-Porosity High-Alumina Bricks: “Dense” and Erosion-Resistant

- Structural Characteristics: Apparent porosity is controlled at 12%–20%, with uniform pore distribution and high sealing rate, resulting in a dense matrix.

- Performance Advantages: Reduced pore channels effectively block the penetration paths of corrosive media such as slag, alkaline vapors, and CO. Significantly superior resistance to chemical erosion and permeation compared to conventional high-alumina bricks.

- Applicable Occasions: Primarily used in furnace linings where they come into direct contact with materials or flue gas, or in areas subject to severe erosion. Examples include cement kiln transition zones, lime kiln firing zones, glass kiln arches, and metallurgical slag lines.

Low-creep high-alumina bricks: Maintaining structure through “shape stability”.

- Structural characteristics. By introducing andalusite or mullite pre-synthetic materials, a needle-like mullite network is continuously generated at high temperatures, forming a micro-expansion self-locking structure; the creep rate is much lower than that of ordinary high-alumina bricks.

- Performance advantages

-

- (1) High-temperature strength: The load softening start temperature is ≥1550℃, and it can withstand mechanical loads and its own weight for a long time without deformation.

- (2) Thermal shock resistance: The matching of the mullite phase and the glass phase results in a moderate elastic modulus.

- (3) Chemical stability: It has good inertness to alkali metals, sulfur, chlorine, and other gaseous phase erosion, and the surface liquid phase viscosity is high, resulting in a firm kiln coating.

- Applicable occasions. Mainly used in high-temperature load-bearing zones that require long-term maintenance of geometric dimensions. Such as the firing zone of cement kilns, the high-temperature zone of pellet kilns, the arch of hot blast stoves, the carbonization chamber of coke ovens, and the burners and crossbeams of various large kilns.

Brief Description of Process Differences

Low-porosity bricks: Contain slag (or some corundum) to fill intergranular voids and promote sintering. Firing temperature is slightly higher, emphasizing “densification.”

Low-creep bricks: Contain andalusite/mullite. Their high-temperature decomposition and secondary mullification generate micro-expansion that counteracts shrinkage, emphasizing “micro-expansion-locked structure.”

Differences in raw material costs lead to different selling prices, but both aim to ensure the long-term safe operation of the furnace lining.

Selection Recommendations

- For areas where chemical erosion and slag penetration are the main failure mechanisms, low-porosity high-alumina bricks should be prioritized.

- For areas where high-temperature loads, structural deformation, and frequent temperature fluctuations are the main failure mechanisms, low-creep high-alumina bricks should be prioritized.

- Different zones within the same kiln can be used in combination: low-porosity bricks should be used in severely eroded sections, while low-creep bricks should be used in high-temperature load-bearing sections to achieve a balance between functionality and economy.

Although low-porosity and low-creep high-alumina bricks both originate from high-alumina bauxite, they each have their own strengths due to differences in auxiliary material selection and process orientation. The former resists erosion with its dense structure, while the latter maintains structural integrity through its shape-stabilizing properties. Only by rationally distinguishing and precisely matching them can the long-term value of high-alumina materials in modern high-temperature industrial furnace linings be fully realized.