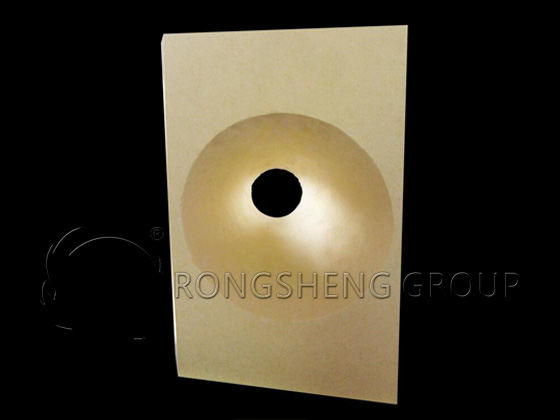

Refractory materials are crucial for ensuring the safe operation of glass furnaces. The configuration and quality of refractory materials used in glass furnaces directly determine the quality of the glass and the lifespan of the furnace. The rapid development of the glass industry has promoted the development and technological advancement of refractory materials for glass furnaces. Rongsheng Refractory Materials Manufacturer supplies refractory materials for glass furnaces, including sintered AZS bricks and fused AZS bricks. Contact Rongsheng for free samples and quotes.

Sintered AZS Bricks for the Glass Industry

Sintered AZS bricks are made primarily from zircon and alumina, using pre-synthesized aggregate as the main raw materials. To achieve dense sintering, measures such as adjusting the critical particle size composition, adding a composite binder and a small amount of TiO2 and MgO sintering aids, and enhancing sintering are required.

Sintered AZS bricks are primarily made from zircon; have a refractoriness of 1630°C; a bulk density of 3.1 g/cm³; and a compressive strength of 100 MPa. Therefore, sintered AZS bricks offer excellent resistance to alkali vapor and thermal shock.

Classification of Sintered Zirconia-Corundum Bricks

Sintered zirconia-corundum bricks (hereinafter referred to as AZS bricks) are made from alumina and zircon, with a ZrO₂ content generally controlled at 15% to 30%. The main crystalline phases are mullite, corundum, and baddeleyite. Under very pure raw material conditions, the glass phase content can be less than 5%. Therefore, the physical and chemical basis for the production of these products is primarily the solid-phase reaction between Al₂O₃ and ZrSiO₄.

This series of products primarily falls into three categories:

① Reaction-sintered AZS products, which feature a microstructure consisting of a uniform distribution of two phases of mullite and baddeleyite (containing some t-ZrO₂). This irreversible reaction is also known as an in-situ reaction. The reaction starts at a temperature between 1370°C and 1420°C.

② Recombined AZS products, made from fused AZS through pulverization, forming, and sintering.

③ Zircon-containing products. These products represent the simplest type of sintered AZS in the broad sense. It is made by sintering coarse particles of sintered or fused mullite, corundum, or calcined bauxite with zircon in any proportion, adding a small amount of clay or other binder. The firing temperature determines whether the zircon particles decompose completely, slightly decompose on the surface, or not decompose at all. Zircon sintered at 1650°C does not decompose at all, but the surface in contact with Al2O3 decomposes at temperatures below 1500°C.

Product Features of Sintered AZS Bricks

① High Refractoriness: Sintered AZS bricks have a high refractoriness, reaching over 1790°C, making them a high-grade refractory material.

② High Refractoriness Under Load: Sintered AZS bricks contain minimal impurities, and the refractoriness under load of aluminum-zirconium products is generally above 1550-1650°C.

③ Good Thermal Shock Resistance: They possess excellent thermal shock resistance.

④ Chemical Resistance: Aluminum-zirconium refractory products exhibit excellent resistance to corrosion, oxidation, and reduction reactions from acidic or alkaline slags and molten metals. This resistance increases with increasing Al2O3 content and decreasing the content of harmful impurities.

To this end, in the production of sintered AZS bricks, the performance indicators and crystal structure of the raw materials, the proportions of the ingredients, and the required particle size composition must be strictly controlled to achieve satisfactory product performance and phase structure.

Preparation of Sintered Zirconia-Corundum Bricks

Key factors in the preparation of sintered AZS products:

① Ensure complete reaction of ZrSiO₄ and Al₂O₃, resulting in dense sintering and a uniform mullite-corundum-baddeleyite clinker with a glass phase content not exceeding 5%.

② The added alumina and kaolin should conform to the mullite composition.

③ Ensure a reasonable particle size distribution to ensure maximum bulk density.

④ Ensure that the product is fully sintered to achieve an ideal microstructure.

Producing high-quality sintered AZS products is challenging. In a sense, the stringent control requirements for process flow are no less stringent than those for fused-cast products. The properties of sintered AZS bricks: High density and strength are closely related to the product’s corrosion resistance and high-temperature performance. To increase green body density during production, the green body must be formed using a mechanical press with a force of 650 tons or higher, and the particle size composition must be appropriately adjusted to achieve a comprehensive increase in density.

Application of Sintered AZS Bricks in Glass Furnaces

Sintered AZS bricks for glass furnaces have a chemical composition of Al₂O₃-ZrO₂-SiO₂. Sintered AZS bricks are made from zircon and alumina as the main raw materials, with a binder added. These bricks are mixed, formed, dried, and then sintered. Currently, sintered AZS bricks for glass furnaces are commonly used in the L-shaped suspended walls of float glass furnaces.

Sintered AZS bricks offer excellent thermal stability, uniform thermal expansion, and excellent resistance to spalling, alkali vapor, and corrosion from batch materials, making them an ideal material for L-shaped suspended walls. The L-shaped suspended wall (also known as the front wall) of a float glass furnace is the front end wall of the flame space in a horizontally flamed glass tank furnace, primarily preventing the flame from escaping from the furnace. They operate in harsh environments, subjecting them not only to the erosive effects of the high-temperature flames, but also to the thermal shock of the overflowing flames, as well as the thermal shock caused by the temperature difference (approximately 1300°C) generated by the incoming materials. The most severe erosion is caused by the high-temperature erosion of various components in the batch flyback. Sintered AZS bricks have a relatively stable and uniform phase composition, which can avoid the reaction between uneven phases under the action of high-temperature glass solution for a long time, and can operate stably for a long time in high-temperature glass solution.