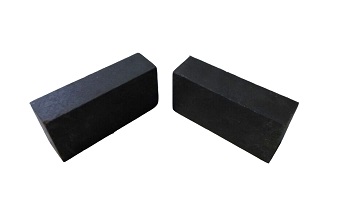

Magnesia carbon brick is a refractory product made of magnesia and graphite as the main raw materials, plus an appropriate amount of binder and then after high pressure molding and low temperature heat treatment. Magnesium-carbon brick was first developed in Japan and is a new type of refractory products in the 1970s. It is mainly used for steelmaking converter, electric furnace lining, refining ladle lining outside the furnace and so on. We are a professional magnesia carbon brick manufacturer with high quality refractory materials, welcome to consult us.

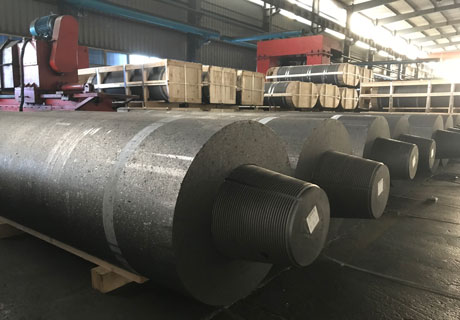

Magnesium-carbon brick is generally non-fired products, and the production process of magnesia carbon brick manufacturer mainly includes raw material processing preparation, batching, mixing, forming, heat treatment and so on. Production magnesia carbon brick to the surface of the magnesia particles, should be completely combined with wetting agent, and then by extruding outside parcel is binder wetting of graphite, the rest of the dispersed graphite or magnesia powder by uniform by binder wetting, various additives and magnesia powder is dispersed evenly, temperature of the mud is suitable, provides good conditions for forming.

This series of refractory brick is a non-carbonized composite refractory material made of high melting point alkaline oxide and high melting point carbon material, with various non-oxide additives and using carbon binder. It is often used for lining of converter, AC furnace, DC arc furnace, slag line of ladle and so on. Magnesium-carbon brick is made of high melting point basic oxide magnesium oxide (melting point 2800℃) and high melting point carbon material which is hard to be infiltrated by slag. A carbon – free composite refractory with a carbon – binding agent.

In general, magnesium-carbon bricks are made from sintered magnesia (98% MgO), fused magnesia (91% MgO), and natural flake graphite (94-95% fixed carbon and 5% ash). The binder is thermosetting phenolic resin and thermoplastic phenolic resin composite binder. The technical indexes of thermosetting phenolic resin are: fixed carbon 80~89%, free phenol 5~6%, free aldehyde 1.2~1.5%, moisture not more than 10%. The additives are mainly aluminum metal powder, silicon powder, SiC and Al+Si powder. Magnesia carbon brick as a kind of composite refractory material, makes good use of the high slag corrosion resistance of magnesia and the high thermal conductivity and low expansibility of carbon, and compensates the biggest shortcoming of the poor spallation resistance of magnesia. Its main characteristics are: good high temperature resistance, strong slag resistance, good thermal shock resistance, low high temperature creep.

Magnesia carbon bricks binder can be divided into phenolic resin, modified asphalt, petroleum cracking by-products. Among them, the phenolic resin with the best use effect and the most dosage. After the reaction of impurity oxides and graphite in this series of refractory materials, the refractory brick structure is loose, the permeability is increased and the strength is decreased, which are the main reasons for the damage of magnesium-carbon brick. Therefore, the production of magnesia carbon brick manufacturer is mostly made of graphite with high purity and large crystallinity of phosphorus tablets.

We are a professional refractory manufacturer, committed to producing more high-quality refractory products, product quality stable and reliable, reasonable price. We are a high quality magnesia carbon brick manufacturer, welcome to consult purchasing.