The fire baffle of brick kiln is an innovative product that can replace the traditional brick kiln hanging refractory bricks. It can improve the adjustment flexibility of the tunnel kiln and reduce the temperature difference in the kiln.

In fact, this fire baffle is a rigid refractory material made of ceramic fiber, which belongs to the aluminum silicate series. It was chosen mainly because the traditional refractory brick hanging structure has safety hazards. Traditional refractory bricks have serious heat loss due to their high density, heavy weight, easy to fall, and high thermal conductivity. At high temperatures, they also exert a large thrust on the kiln wall, increasing the risk of brick collapse.

Ceramic fiberboard has gradually become a popular material in the field of fireproofing and thermal insulation due to its unique properties. This board weighs only one-seventh of the traditional insulation material refractory brick, and its thermal conductivity is only one-tenth of conventional insulation materials. It can remain intact even at temperatures as high as 1200 degrees Celsius. Within the temperature resistance range, its thermal conductivity coefficient does not increase with the increase of temperature. In addition, it has the advantages of easy construction, convenient maintenance, and high cost reduction and efficiency. Its cost is comparable to that of refractory bricks, or even lower in some cases.

Main Advantages of Ceramic Fiberboard

- In the preheating zone, it can be used to form a kiln-sealing air curtain, effectively isolating the outside world and reducing heat loss.

- Inside the drying zone, it helps to reduce the stratification of hot air flow, promote uniform temperature distribution, and prevent products from cracking due to excessive temperature difference.

- In the firing zone, ceramic fiberboard can adjust the pressure in the kiln, increase the turbulence of hot flue gas, and thus reduce the temperature difference on the same cross section.

- In the cooling zone, by reasonably setting the ceramic fiber fire baffle, the temperature can be adjusted to ensure product quality and avoid cracking caused by too fast cooling.

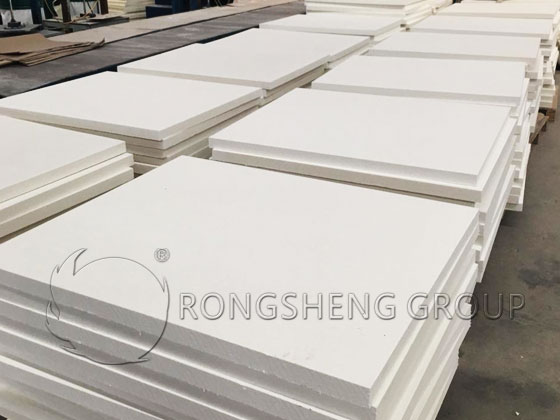

Application of Ceramic Fiberboard

For different areas, the structural design of the fire baffle adopts modular combination to adapt to different temperature difference requirements. The specific settings are as follows:

In the preheating zone, it is recommended to set 2 to 3 fire baffles.

At the junction of the preheating zone and the low temperature zone of the firing zone, set 1 fire baffle.

In the medium and high temperature zones of the firing zone, set 1 to 2 fire baffles.

At the junction of the high temperature zone of the firing zone and the rapid cooling zone of the cooling zone, set 1 to 2 fire baffles.

At the junction of the rapid cooling zone and the slow cooling zone of the cooling zone, set 1 to 2 fire baffles.

In the slow cooling zone of the cooling zone, it is recommended to set 3 to 5 fire baffles.

For special products, adjustments should be made according to specific circumstances.

Why does the Ceramic Fiberboard Crack when It is Used?

Ceramic fiberboard is a very good refractory material with very strong performance, so generally speaking, it will not suddenly crack during use. If the ceramic fiberboard suddenly cracks when it is used, it may be that the material quality of the ceramic fiberboard is not up to standard and there are certain problems, so it cannot be used. However, what exactly is the reason why the ceramic fiberboard suddenly cracks when it is used?

- During the heat treatment of ceramic fiberboard, due to the high temperature, the carbide is completely dissolved and the grains are coarse. At the same time, the tempering is not sufficient, resulting in increased residual stress and increased brittleness.

- During the grinding of ceramic fiberboard, due to the excessive feed amount, the cooling is insufficient, resulting in large thermal stress and tissue stress on the surface, which is superimposed with residual stress and is easy to cause grinding cracks.

- The wrong use of ceramic fiberboard causes external force to cause the board to suddenly crack during use.

Therefore, whether it is when buying ceramic fiberboard or before using it, relevant inspections must be done. First, make sure that the quality of the purchased ceramic fiberboard is not a problem, and then use it in the correct way. This can largely avoid the phenomenon of sudden cracking of ceramic fiberboard during use.