Because of the relatively high aluminum content of corundum castables, the price will be a little higher than that of ordinary castables. But good products last longer. Just like corundum castables, because of their high aluminum content, they are used longer than other castables. However, there are two types of corundum castables that we often see. One is a corundum-based high-strength wear-resistant refractory castable, and the other is a corundum-mullite high-strength wear-resistant refractory castable. The two castables that seem to contain corundum are actually quite different in terms of performance. So, what is the difference between corundum and corundum mullite? – Properties of refractory raw materials. Rongsheng refractory material manufacturer is a refractory material manufacturer with rich experience in production and sales.

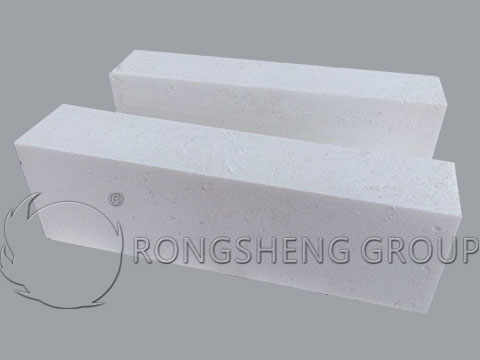

Corundum Refractory Brick

Corundum refractory bricks, chrome corundum refractory bricks, titanium corundum refractory bricks, etc. Refractory bricks containing more than 90% Al2O3 are called corundum refractory bricks, also known as pure alumina refractory bricks. Corundum has a high hardness (9 on the Mohs scale) and a high melting point. These are closely related to the firmness of the Al—O bond in the structure. Therefore, a-Al2O3 is the main phase for making high-temperature refractory bricks and high-temperature electrical insulation materials. Corundum refractory bricks have good stability against the action of acid, alkaline slag, metal, and glass solution. It can be used in an oxidizing atmosphere at high temperatures or in a reducing atmosphere, and it can receive good results. The basic material of corundum refractory bricks is fused corundum or sintered corundum.

The Difference between Refractory Raw Material Corundum Mullite and Corundum

The difference between corundum and corundum mullite is mainly in performance. Corundum-based high-strength wear-resistant refractory castables mainly have better wear-resistant and refractory properties, while corundum mullite-based high-strength wear-resistant refractory castables mainly have better thermal shock resistance. However, Rongsheng refractory manufacturers can be sure that the aluminum content of corundum mullite castables is not as high as that of corundum high-strength castables.

When it comes to the difference between corundum and corundum mullite, first let us talk about the properties of these two raw materials, corundum, and mullite. The main component of corundum is α-Al2O3, which belongs to the triangular crystal system, and the crystal is short columnar. The true density is 3.85~4.01g/cm~3, the hardness is 9, and the melting point is about 2050℃. In addition, corundum itself has high thermal conductivity and insulation, good chemical stability, and the ability to resist the action of reducing agents.

Therefore, corundum can be used as a raw material for advanced refractory materials. Mullite is rare in nature. Generally speaking, the raw materials used as refractory materials are artificially synthesized. The raw material of mullite itself has high purity, high density, and a good organizational structure. It has the advantages of a low creep rate, small thermal expansion, good thermal shock resistance, and strong chemical corrosion resistance. It has been widely used in the refractory industry.

During the construction of circulating fluidized bed boilers, the main refractory materials used are refractory bricks and castables. When castables are used as boiler linings, the two most commonly used are corundum and corundum mullite. So what are the main differences between corundum and corundum mullite?

I believe that after understanding the above information, you should have a general idea. Adding corundum to the refractory castable can make the aluminum content of the castable reach more than 90%, which improves the hardness and strength of the castable. However, if corundum and mullite are added to the castable, the aluminum content can reach 99%, the hardness, strength, and wear resistance can reach a certain range, and the application effect is also remarkable.

However, what we need to pay attention to is that when we use them, we often see corundum wear-resistant refractory castables and corundum mullite wear-resistant refractory castables. Even if you buy other types of castables, some refractory manufacturers will add more or less corundum or mullite raw materials when producing wear-resistant refractory castables to improve the hardness and construction effect of the castables. Therefore, it can be seen that castables can play a stronger role and further save customers money.

Selection of Refractory Castables for Refractory Lining of High-Temperature Kiln

Corundum mullite refractory castable is actually a castable with better performance than corundum refractory castable. For the type of castable used in the boiler, it is still necessary to determine the corresponding refractory material according to the use of the boiler.

The corundum contained in the preparation of corundum-based refractory castables is a trigonal crystal system, and the crystal form is generally short columnar. Corundum itself also has high thermal conductivity and electrical insulation properties, excellent chemical stability, and the ability to resist the action of reducing agents. Therefore, corundum is a high-grade refractory raw material in unshaped refractory materials. Corundum is generally made of industrial alumina or bauxite after sintering or electric melting, so it is artificial corundum used in industry. However, the density and hardness of artificial corundum are relatively large, so its use effect is also relatively significant.

The mullite contained in the corundum mullite refractory castable is relatively small in nature. The mullite raw materials used in industry are all artificially synthesized. It has the advantages of high purity, relatively high density, good organizational structure, low creep rate, small thermal expansion, good thermal shock resistance, and strong chemical corrosion resistance. It is widely used in the refractory industry, and it develops relatively rapidly. However, if you compare corundum with mullite, the hardness and true density of corundum are much better than that of mullite.

The difference between corundum and corundum mullite is mainly in performance. Corundum refractory castables are mainly resistant to wear and fire, while corundum mullite refractory castables are mainly resistant to thermal shock. The aluminum content of corundum-mullite castables is not as high as that of corundum-based high-strength castables. But the flexibility of corundum mullite castable is better.

Rongsheng Refractory Material Manufacturer

Rongsheng Refractory Material Manufacturer is a powerful refractory production and sales enterprise. Rongsheng’s refractory products have passed strict technical tests before leaving the factory. Finally, it is packaged and shipped out of the factory to meet or exceed the customer’s use requirements and index requirements. And no matter what kind of problems customers have in use, the after-sales service of Rongsheng refractory manufacturers is also a solution to various unknown problems that arise in the process of customers’ use. Until the customer’s high-temperature furnace lining can operate normally. Rongsheng refractory manufacturers’ high-quality corundum, steel, and mullite refractory products can also provide turnkey projects. Contact us for free price information and sample service.