New environmentally friendly processes and reduced pollutant emissions are the new driving force in the steelmaking industry. Magnesia-chrome bricks fired at temperatures above 1700°C are used for permanent lining of ladles in the production of stainless steel, due to their high physical and mechanical properties and dimensional stability. Tempered refractory bricks use a special binder that eliminates the burning of fossil fuels and there is no CO2 emission from the combustion process. The new refractory bricks are based on MgO-ZnO with free chromium and carbon. This article describes the properties and results of sintered and tempered bricks used for safe refractory lining of ladles in the production of stainless steel.

During the secondary metallurgical refining of stainless steel, molten steel is fed into ladles for transportation and alloying. Ladles are made of different refractory grades, depending on the erosion mechanisms present during operation. In this context, the common state of affairs in ladles producing stainless steel is to use calcined dolomite refractory bricks for the working lining and magnesia-chrome bricks for the permanent lining.

Calcined dolomite bricks, whose two main components are CaO and MgO, are commonly used in silicon-killed steel production due to their high compatibility with basic slags and low cost. Direct bonded calcined dolomite bricks are fired at high temperatures in tunnel kilns until a ceramic bond is formed. Although the presence of CaO makes the bricks hydration sensitive, it plays a crucial role in the chemical behavior of the material. The slag resistance of calcined dolomite bricks is due to free lime, which is able to form a dense Ca2SiO4 (C2S) layer, which has a high refractoriness (2154°C) and protects the material from further penetration and erosion by slag.

Different types of stainless steel are produced in the same ladle, which makes the process adaptable to a wide range of refractory requirements. Magnesia-chrome bricks are often used for safe permanent lining of stainless steel ladles due to the high chromium content of this stainless steel type, as it is compatible with the process. These bricks are known for their ability to form a ceramic bond during sintering due to secondary spinel formation, which is responsible for high mechanical properties, corrosion resistance, erosion and thermal stability.

The presence of “complex spinel”, (Mg, Fe) [Cr, Al, Fe]2O4) in the microstructure plays an important role in the thermodynamic properties of MgO-Cr2O3 refractory bricks. Secondary spinels help to form direct bonds between grains and prevent slag attack, they may be formed by precipitation of spinel-rich silicate liquid phase or precipitation during cooling of solid solution. Intergranular spinel forms within MgO grain boundaries, and intragranular spinel forms within MgO grain boundaries.

Magnesia-chrome refractory bricks are divided into direct bonded, rebound, semi-rebound, and a new tempered zero-carbon material has been developed in recent years. Regardless of the production process, all grades have a high chromium content. Therefore, under normal industrial temperature and oxidizing conditions (in air), the trivalent chromium (Cr3+) present in MgO-Cr2O3 refractory can be oxidized to Cr6+. The formation of hexavalent chromium is catalyzed by alkaline environment, slow cooling rate, small grains, the presence of CaF2 and low temperature. This component is soluble in water and is known to be carcinogenic. Due to stricter environmental regulations, the steelmaking industry is aware of this problem and has made great efforts to recycle and reduce solid emission waste.

Steelmaking consumes a lot of refractory materials. Most of the refractory materials commonly used in ladles in stainless steel production are fired at high temperatures, which will release a lot of carbon dioxide. In order to reduce pollutant emissions, a new zero-carbon content environmentally friendly refractory brick binder system has been developed as an alternative to currently fired refractory materials.

In this context, zero carbon tempered MgO-ZnO refractory bricks were developed as an alternative solution for the permanent lining of ladles in stainless steel production. Due to its rapid sintering ability, this new material is able to develop ideal properties while using the energy already present in the process, allowing the refractory bricks to be delivered to customers in a tempered condition at 200°C. The new refractory bricks do not contain chromium, are easier to recycle, and have less carbon dioxide emissions due to the elimination of the firing process and shorter delivery times. The following introduces the performance comparison and user results of calcined MgO-Cr2O3 refractory bricks and tempered MgO-ZnO refractory bricks.

Customer Trials

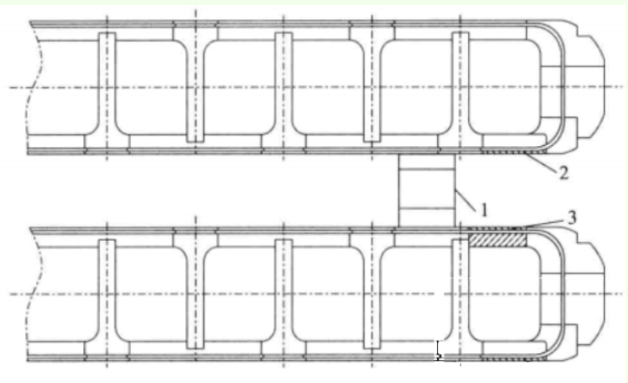

Several tests were conducted for customer A on the safety lining of a stainless steel ladle. Both refractory bricks were always assembled and used in the same ladle. The following sections will highlight some of the test results.

Test A: 93 tempered MgO-ZnO bricks (230×65×70 mm) were assembled and masonryed in the same equipment ladle container as the fired MgO-Cr2O3 refractory bricks to ensure the same operating conditions. During the entire production process, a total of 8 different grades of stainless steel were produced, which ended in 42 furnaces due to erosion of the calcined dolomite refractory bricks used. After the test, no abnormalities were found in the MgO-ZnO bricks.

Test B: 300 tempered MgO-ZnO bricks (230×65×70 mm) were assembled on the same ladle as the fired MgO-Cr2O3 bricks to ensure the same operating conditions. Four different grades of stainless steel were produced during the production process, which ended after 30 furnaces due to erosion of the calcined dolomite bricks used in the slag working lining. The MgO-ZnO bricks used for the safety permanent lining were removed and inspected and had a good appearance after sintering.

Conclusion

The tempered bricks after heat treatment showed good properties due to the presence of the binder system and zinc oxide, which diffused into the magnesium oxide to form a solid solution. The combination of zero carbon binder and zinc oxide increased the efficiency of the sintering process.

Tempered magnesia bricks for stainless steel safety linings have been developed using a unique zero carbon, zero chromium binder system. The newly developed product is an environmentally friendly alternative for stainless steel ladle safety linings. The customer trials presented in this article showed very good results and new trials are underway to consolidate the technology.

Note: This article comes from the Internet. For more specific refractory product information, please contact us.