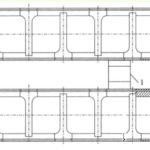

As is known to all, a hot blast furnace is a thermal equipment that heats the air pumped into the blast furnace from normal temperature to high temperature. Equipment types are mainly divided into internal combustion type and external combustion type. The furnace is mainly composed of a regenerator and a combustion chamber. Professional refractory material for sale, high degree of production automation, stable and reliable refractory products, welcome to consult procurement.

Hot blast furnace usually uses the mixed gas of blast furnace gas and coke oven gas as fuel to heat the air to 1300~1600℃. Under the mechanical load and high temperature, the masonry will shrink and crack, which will directly affect the service life of the hot blast furnace. Also because of these, for hot blast furnace refractory material requirements of hot melt, creep resistance, high softening temperature under load, high temperature strength, but also has a good thermal shock resistance.

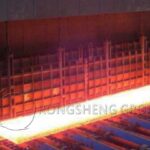

However, Refractory material for sale,when the hot air temperature (less than 900℃) is low, you can choose clay bricks to meet the requirements. When the hot air temperature is 900~1100℃, the high temperature furnace lining and grid brick should be made of high alumina brick, mullite brick or sillimanite brick. When the hot air temperature is 1100~1200℃, high alumina brick, mullite brick, sillimanite brick or silica brick should be used for lining and checker bricks at high temperature. Above 1200℃, high temperature furnace lining and grid brick should use high quality silicon brick, mullite brick and sillimanite brick.

Refractory material for sale it is worth our attention that more and more refractory balls with high strength and low creep are used in hot blast furnace. High strength and low creep refractory balls are characterized by large surface area, strong heat storage capacity, high thermal efficiency, remarkable energy saving effect, and significant improvement of hot air temperature. It is simple and convenient in masonry and has the advantage of saving working hours. Effectively solve the problem of adhesion.

We are a professional refractory materials manufacturer, with 3 high-temperature tunnel kilns, high degree of production automation, considerable output, welcome to consult and purchase, we will serve you wholeheartedly.