With the advancement of ladle refining technology, melting temperatures and times have increased, making the operating environment of ladle refractories increasingly demanding. Corundum self-flowing castables are primarily used to fill gaps around air bricks and base bricks. During use, they are subject to mechanical erosion from molten steel tapping and argon-blowing stirring. Intermittent production also causes significant temperature fluctuations. At the end of the casting phase, they are also chemically attacked by the ladle slag.

To ensure that the lifespan of corundum self-flowing castables matches that of base bricks and air bricks, high-quality refractory raw materials must be used. Since the second half of 2021, raw material prices have risen significantly, directly increasing the cost of corundum self-flowing castables. Therefore, it is imperative to find a low-cost, high-performance refractory raw material that can match the lifespan of corundum self-flowing castables with that of base bricks and air bricks, while also reducing costs. Calcium aluminotitanate, a byproduct of ferrotitanium smelting, offers advantages such as low price, low porosity, and excellent high-temperature performance. It can be researched and applied in corundum self-flowing castables to reduce costs.

Material Composition of the New Corundum Self-Flowing Castable

The aggregate for the new corundum self-flowing castable is primarily calcium aluminate titanate (5-3mm, 3-1mm, and 1-0mm). The matrix comprises fused white corundum powder (0.074mm), activated α-alumina fine powder (d50 ≤ 1.5µm), SiO2 fine powder (d50 ≤ 0.5µm), pure calcium aluminate cement, and a water reducer.

In the experiment, the conventional corundum self-flowing castable formulation was adjusted by adjusting the type and amount of aluminum fine powder. After selecting the optimal formulation, actual industrial testing was conducted. After mixing the ingredients according to the sample composition, the castable was placed in a mixing pot and stirred with water for 3 minutes. The castable was then self-flowed into 40mm × 40mm × 160mm specimens. After natural curing and demolding, the castable was baked at 110°C for 24 hours and finally heat treated at 1500°C for 3 hours. Tests include self-flow value, apparent porosity, bulk density, room temperature compressive strength and flexural strength, linear change rate, and high temperature flexural strength. Slag erosion resistance test characterizes the material’s erosion resistance based on slag erosion conditions.

Performance changes of new corundum self-flowing castables

Self-flowing performance

In order to meet the requirements of self-flowing construction and construction time of corundum self-flowing castables, it is very necessary to measure the self-flow value and observe the bleeding situation. The test temperature is room temperature 30℃, and the initial self-flow value, 30min self-flow value and bleeding situation of each group of materials are observed and tested. The following characteristics can be obtained from the test results:

(1) The self-flow value decays with the extension of time, and the rule of each group is T0>T30.

(2) Under the same conditions, the initial self-flow value of each group of samples is different, but there is no situation where flow decay cannot be constructed. The main reason why each group of samples has good self-flowing performance is that the water-reducing agent particles wrapped on the surface of the micropowder are tightly combined with the micropowder. During the static process, the micropowder ions continue to remain in a discrete state, resulting in a better initial self-flow value and a longer self-flowing performance.

(3) As the amount of aluminum micropowder added increases, the amount of water added to the sample gradually decreases, and the initial self-flow value increases. However, when the amount of aluminum micropowder added is too much, the self-flow value increases slowly. When the aluminum powder addition level was 10%, and when the composite aluminum powder addition level was 10% and 12.5%, the samples began to seep water during standing. This is largely due to the addition of aluminum powder.

- On the one hand, aluminum powder fills capillaries, releasing free water within them, reducing viscosity and rapidly increasing the flow rate.

- On the other hand, it contributes to increasing the suspended particle concentration and overall adsorption activity, increasing viscosity and thus slowing the increase in the flow rate.

Physical properties at room temperature

(1) The trend of changes in bulk density and porosity of each group of samples after heat treatment at 110℃ and 1500℃. From the test results, it can be seen that with the increase of the amount of aluminum powder added, the bulk density of the sample gradually increases and the porosity gradually decreases.

(2) The trend of changes in strength of each group of samples after heat treatment at 110℃ and 1500℃. From the test results, it can be seen that with the increase of the amount of aluminum powder added, the strength of the sample gradually increases.

The main reason for the above situation is that the increase of active aluminum powder is conducive to increasing the bulk density, improving its organizational structure, and thus increasing the strength.

(3) The trend of changes in the linear change rate of each group of samples after heat treatment at 1500℃. From the test results, it can be seen that:

- The shrinkage of the groups of samples with composite powder added is slightly smaller.

- The shrinkage of the sample increases with the increase of the amount of aluminum powder added.

This situation is related to the sintering performance of aluminum powder.

High-temperature physical properties

The high-temperature flexural strength of each group of samples at 1400℃ for 0.5h. The test results show that:

- (1) The hot flexural strength of the new corundum self-flowing castable using calcium titanate gradually increases with the increase of aluminum micropowder addition.

- (2) The high-temperature flexural strength of the sample using composite aluminum micropowder is slightly lower.

- (3) The hot strength of sample 4# is similar to that of conventional corundum self-flowing castable, reaching about 3.1 MPa.

Slag resistance performance

The cross-section of the slag resistance samples of each group of samples after heat treatment at 1500℃. From the test results, it can be seen that:

- (1) With the increase of the amount of aluminum micropowder added, the slag erosion resistance of the material gradually improves.

- (2) The slag resistance of the sample using composite micropowder is slightly worse.

The main reason for this is that with the increase of the amount of aluminum micropowder added, the porosity of the material gradually decreases, and the room temperature and hot state strength are improved, which can effectively prevent the penetration and infiltration of slag, thereby gradually improving the slag resistance.

Practical Application Case Analysis of the Improved Self-Flowing Castable

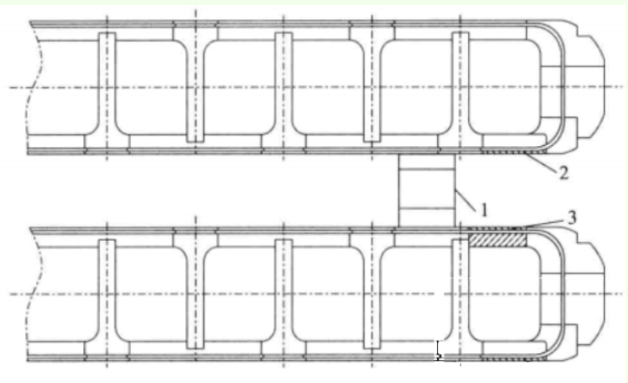

Actual Industrial Application. A comparison of physical and chemical indicators and construction performance shows that the self-flowing properties of the new corundum self-flowing castable meet on-site construction requirements, and its physical properties also meet the required physical and chemical indicators. Therefore, the new corundum self-flowing castable was selected for industrial testing. Industrial testing was conducted on 150-ton ladles at a steel plant, with ladle #12, ladle #15, ladle #22, and ladle #25. The material’s self-flowing properties and construction time during on-site construction met on-site requirements, and no abnormalities were observed during the service life of the four ladles. Inspection of the ladle bottom after the ladle was off the production line revealed that the corundum self-flowing castable performed well, with its lifespan roughly matching that of the air bricks and seat bricks. No steel seepage or abnormal corrosion was observed during replacement of the seat bricks and air bricks. This demonstrates that the new corundum self-flowing castable meets on-site requirements.

Economic Benefit Analysis. A comprehensive analysis of the economic benefits of the new corundum self-flowing castable compared to conventional corundum self-flowing castable was conducted. The specific results show that the comprehensive material cost of the new self-flowing corundum castable developed with calcium titanate as the aggregate is 3,680 yuan/ton, while the comprehensive cost of conventional self-flowing corundum castable is 5,600 yuan/ton, a cost reduction of approximately 2,000 yuan per ton. For example, in a steel plant with an annual steel production capacity of 5 million tons, the base bricks and air bricks of a 150-ton ladle are replaced after 30 uses. At this time, the amount of re-casting corundum self-flowing castable is approximately 0.5 tons, and the annual consumption of corundum self-flowing castable is approximately 700 tons. This results in a comprehensive cost reduction of approximately 1.4 million yuan per year, a considerable economic benefit.

Advantages of the application of new self-flowing castables in steel ladles

In order to meet the goal of reducing the cost of steel ladles, a series of tests were carried out on the basis of conventional corundum self-flowing castables, and a new type of corundum self-flowing castable was researched and developed. It was actually applied in a 150-ton steel ladle in a steel plant, and an economic benefit analysis was conducted. The following conclusions were drawn:

- (1) The construction performance and physical properties of the new corundum self-flowing castable can meet the requirements.

- (2) The selected new corundum self-flowing castable scheme was industrially tested in a 150t steel ladle. The service life basically matched that of the base bricks and breathable bricks, meeting the requirements of on-site use and having a good use effect.

- (3) Taking an annual output of 5 million tons of steel as an example, the new corundum self-flowing castable can reduce the cost by about RMB 1.4 million per year, with considerable economic benefits.

The new corundum self-flowing castable can not only meet the service life requirements of the steel ladle, but also significantly reduce the material cost and can be widely promoted and applied.