The basic material composition of ordinary refractory ramming materials is basically similar to refractory castables and plastics, and it is also composed of refractory aggregates, powders, binders, and additives in proportion. The difference between them is that the amount of powder in the ramming material is more, and the amount of binder is less. Soft clay is usually added to increase the viscoplasticity and sinterability of the material, and the construction is carried out by ramming. Therefore, it is called refractory ramming mass material. Next, the refractory manufacturer will introduce the refractory ramming material to understand whether the construction of the intermediate frequency furnace ramming material at room temperature is related to the furnace age.

What is Refractory Ramming Material?

Compared with refractory castable, refractory ramming material is semi-dry and loose. Under normal circumstances, the ramming material has no cohesiveness before forming, and only by strong ramming can it have a dense structure.

The strength of refractory ramming material is relatively low at room temperature before being sintered, and the strength is not very high even at medium temperature. Only when the carbon compounds in the bonding agent are coked during heating can a strong bond be obtained.

Compared with castables and plastics refractory, refractory ramming materials have higher stability and corrosion resistance at high temperatures. However, the service life of the ramming material actually depends on the amount of pre-sintering before use or the first sintering. If the heating surface of the ramming material is sintered as a whole without cracks and does not stratify with the bottom layer, its use effect will be much improved.

Ramming Material for Intermediate Frequency Furnace

The composition of the ramming material of the intermediate frequency furnace is based on the needs of users, and the ramming material can be prepared from various refractory aggregates and powder materials. At the same time, the appropriate binder should be selected according to the refractory aggregate material and use requirements. Some ramming materials do not use bonding agents and only add a small amount of flux to promote their sintering. Sodium silicate, ethyl silicate, and silica gel are commonly used as binding agents in acid ramming materials. Alkaline ramming materials use aqueous solutions of magnesium chlorides and sulfates, as well as phosphates and their polymers as binders, and often use organic compounds and temporary binders that contain carbon and form carbon bonds at high temperatures.

Construction of Ramming Material for Intermediate Frequency Furnace

The age of the ramming material of the intermediate frequency furnace and the construction quality are very important, and its quality is closely related to the use effect. The ramming material of the intermediate frequency furnace is usually rammed with an air hammer or a ramming machine, and the thickness of the ramming material is about 50-150mm once. The ramming material of the intermediate frequency furnace can be constructed at room temperature. For example, if the thermoplastic organic material that can form a carbon bond is used as the binder, the hot mixing method is used to mix the mixture evenly, and then the construction will be carried out immediately. After molding, according to the hardening characteristics of the mixture, different heating methods are adopted to promote hardening or sintering. For the ramming material containing an inorganic chemical bond, when it hardens by itself to reach a certain strength, it can be demoulded and baked. The material containing the thermoplastic carbon bonding agent will be released from the mold after it has cooled to considerable strength. After demolding, it should be heated quickly to carbonize it before use. It does not contain binder materials that harden at room temperature and is often sintered with a mold after tamping.

The sintering of the ramming material lining of the intermediate frequency furnace can be done in advance before use or can be completed by heat treatment with a suitable thermal system during the second use. The baking and heating system of the ramming material of the intermediate frequency furnace varies according to the material. The main purpose of the ramming material is to build the lining of the smelting furnace that is in direct contact with the melt, such as the blast furnace tapping trough, the bottom of the steelmaking furnace, the lining of the induction furnace, the top of the electric furnace and the blanking part of the rotary kiln. In addition to forming the overall furnace lining, large prefabricated components can also be manufactured.

Contact Rongsheng Manufacturer

Rongsheng Monolithic Refractory Manufacturer

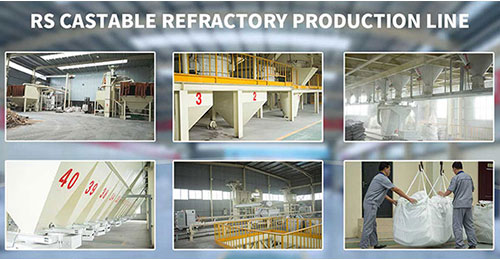

Rongsheng is an experienced manufacturer of refractory materials. Rongsheng’s refractory products have been sold to more than 60 countries around the world. Rongsheng’s advanced environment-friendly and fully automatic unshaped refractory production line have an annual output of 80,000 tons. We provide integral refractory lining materials for various thermal furnace equipment. For example, various wear-resistant refractory castables, refractory ramming materials, plastics, etc. If you need to buy unshaped refractory or refractory brick products for an intermediate frequency furnace, please contact us. We will provide you with services according to your specific needs.