Phosphoric acid hardly reacts with acidic oxides at room temperature and does not harden; therefore, it is not suitable as a binder for acidic refractories. Phosphoric acid reacts with amphoteric oxides (such as Al2O3) at room temperature to form a hard solid, and the reaction rate between them can be controlled, making it particularly suitable as a binder for high-alumina refractories.

Hardening Mechanism of Phosphate Refractory Castables

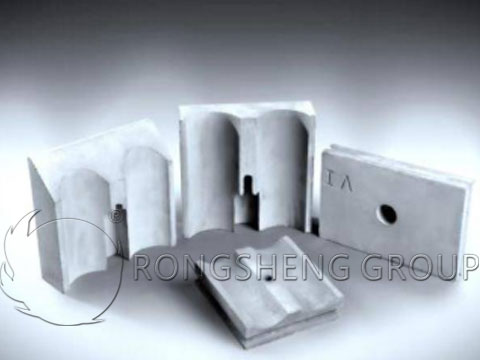

Phosphate castables refer to castables bound with phosphoric acid or phosphates. Their hardening mechanism is related to the type of binder used and the method of accelerating hardening.

The binder for phosphate castables can be phosphoric acid or a mixed solution of phosphoric acid and aluminum hydroxide to form aluminum dihydrogen phosphate. At room temperature, the binder generally does not react with aluminosilicate materials (except for iron). Heating is required to dehydrate and condense the binder, causing it to adhere and bind the aggregate powder together, thus achieving room temperature strength.

When using a setting accelerator, heating is not necessary. Magnesia powder or high-alumina cement can be added to accelerate setting. When magnesium oxide powder is added, it reacts rapidly with phosphoric acid to form phosphates, causing the refractory material to set and harden. When aluminate cement is added, phosphates with good cementing properties, such as hydrated phosphates like monocalcium phosphate or dicalcium phosphate, are formed, causing the material to set and harden.

The hardening mechanism of phosphoric acid and phosphate refractory castables shows that only when the reaction rate between the binder and the refractory aggregates and powders is appropriate during heating can a high-quality refractory castable be formed. However, during the re-crushing, ball milling, and mixing of refractory raw materials, impurities such as metallic iron are easily introduced. These impurities will react with the binder during mixing, releasing hydrogen gas, causing the refractory castable to swell, have a loose structure, and reduce its compressive strength.

Summary of Several Disadvantages of Phosphate-Bound Zircon Ramming Mix

Zircon has high refractoriness, a low coefficient of thermal expansion, good thermal shock stability, and excellent resistance to erosion by molten steel and alkaline slag. Therefore, zircon has long been used as a high-grade refractory material. However, with the widespread application of oxygen-enriched combustion technology, the increase in melting temperature of glass melting furnaces, and the development of overall sealing and insulation technology for glass furnaces, the operating environment for bottom ramming mixes has become more demanding.

Furthermore, the use of recycled crushed glass as a component of the batching material by various glass companies means that metallic impurities from the recycled glass will deposit at the bottom of the furnace, gradually seeping into the ramming layer, forming a “downward drilling” erosion that exacerbates the erosion and damage to the bottom ramming mix.

Zircon ramming mixes are monolithic refractory materials, and the amount of binder, water, and curing conditions added during construction have a significant impact on their performance. Currently, most zircon ramming mixes use phosphoric acid or phosphates as binders. Phosphates are hygroscopic, and phosphoric acid or phosphate binders can react with certain components in the ramming mix, easily creating large pores. At high temperatures, harmful P2O5 transfers and volatilizes, forming low-melting-point compounds, which also reduces the high-temperature performance of the ramming mix. To reduce the cost of zircon ramming mix, improve construction efficiency on-site, enhance its quality, and extend its service life, several disadvantages of phosphate-bonded zircon ramming mixes are summarized.

Currently, phosphoric acid bonding is commonly used for zircon ramming mixes. However, phosphoric acid bonding has several drawbacks:

- ① Phosphoric acid reacts with impurities in recycled zirconium corundum powder, creating pores and reducing the erosion resistance of the zircon ramming mix.

- ② Phosphoric acid-bonded zircon ramming mixes do not harden at room temperature, failing to provide strength and requiring the addition of a hardening accelerator. However, the addition of hardening accelerators introduces more impurities, which is detrimental to the long-term use of the zircon ramming mix.

- ③ Under prolonged high temperatures, P2O5 will transfer and volatilize, reducing the strength of the zircon ramming mix and affecting its service life.

Processes for Eliminating Bulging in Phosphate-Bound Refractory Castable Liners

1) Settling the Material

Mix approximately 3/5 of the amount of refractory aggregate and powder with the binder, place the mixture in a silo or settling area, and cover it with plastic sheeting to prevent binder evaporation. It must not come into contact with water, and the temperature should be above 15℃. Let it stand for a period of time to allow the binder to fully react with the metals in the refractory aggregate and powder, releasing hydrogen gas.

2) Washing and Magnetic Separation

Use methods such as grinding with a ceramic ball mill, washing the powder with strong acid (such as hydrochloric acid), and magnetic separation to minimize or remove metal and other impurities.

3) Inhibitors

Reducing the amount of binder in the refractory material or adding inhibitors can also reduce refractory castable bulging.

Proper Storage Method for Phosphate-Bound Refractory Castables

For large-scale production of phosphoric acid and phosphate-based refractory castables using methods such as vibration molding, setting is an effective and economical method, and therefore widely used. After weighing the settling material, add an accelerator and stir evenly, then add the remaining binder and continue stirring for 1-2 minutes before use. The setting time is mainly determined by the chemical reaction rate between the binder and the metals embedded in the refractory aggregates and powders, as well as environmental temperature and other conditions.

Phosphate-bound refractory castable samples can be stored indoors, outdoors, and in a standard curing room. With increasing storage time, its room temperature compressive strength increases, but indoor storage is better than outdoor storage. The strength after 3 months of standard curing shows a slow decreasing trend. When stored indoors, the post-firing compressive strength is more than 10 MPa higher than that outdoors. The post-firing compressive strength of samples stored in a standard curing room is also better than that of samples stored outdoors. Samples stored outdoors may experience lower performance due to temperature changes and wet/dry cycles.

It should be noted that while the storage environment has some impact on the room temperature properties of phosphoric acid and phosphate refractory castables, it has little impact on their high-temperature properties and does not affect their use. This is because below 200℃, the cemented phosphate formed by the addition of accelerators plays a dominant role, while at high temperatures, the ceramic bond becomes dominant. Therefore, the storage requirements for phosphoric acid and phosphate refractory castables with added accelerators are not very strict after hardening. Phosphoric acid and phosphate refractory castables without added accelerators must undergo heat treatment before storage. Without heat treatment, they lack strength, and at low heat treatment temperatures, they are prone to deliquescence.

Although the binder in phosphate castables does not react with the material itself at room temperature, it can slowly solidify and harden due to temperature changes or other environmental changes during storage or transportation. For long-term storage, retarders such as citric acid and tartaric acid can be added to extend the shelf life.

During storage or under low-temperature conditions, white crystalline substances may precipitate on the surface of phosphoric acid and phosphate refractory castables. Chemical and X-ray analysis revealed that the “white fuzz” was composed of crystals of aluminum and calcium salts. Under high temperature or prolonged heating, the aluminum and calcium salts transform into insoluble salts, and the “white fuzz” disappears. This phenomenon generally does not affect the performance of refractory castables. However, excessive precipitation can lead to a loose internal structure, reduced strength, and even disintegration of the castable; therefore, care should be taken during storage and use.