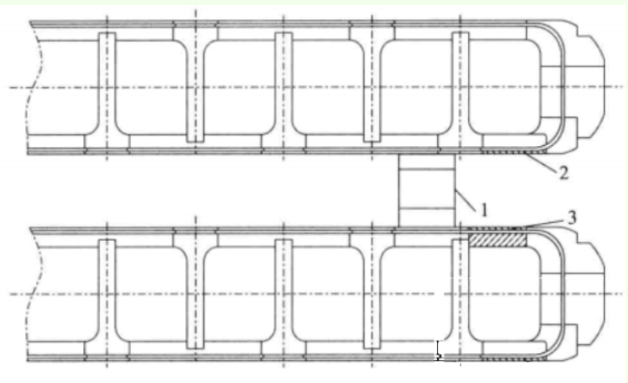

Burner, as the popular name of the combustion device on the industrial fuel furnace, can be understood as “fire nozzle”, and the burner brick is an indispensable and important part. The burner is generally equipped with a fuel inlet, an air inlet and an ejection hole, shouldering the important mission of distributing fuel and combustion air, and allowing the two to be ejected in a specific way to achieve combustion. The burner brick plays a pivotal role in the entire combustion system, and has a vital impact on the efficient combustion of the fuel, the precise shaping of the flame shape and the stable maintenance of the combustion process.

Material Classification of Burner Bricks

Chrome corundum burner bricks

Chrome corundum burner bricks are made of high-purity chrome corundum materials. Chrome corundum has excellent high temperature resistance and can withstand extremely high flame temperatures. It can still maintain stable physical and chemical properties in high temperature environments. At the same time, it also has excellent corrosion resistance and has strong resistance to various corrosive gases and substances produced during fuel combustion. This material of burner bricks is suitable for industrial kilns in high temperature and high corrosion environments such as glass melting furnaces and high-temperature ceramic kilns. Under harsh working conditions, it can operate stably for a long time to ensure the normal operation of the burner and efficient production of the kiln.

Corundum-mullite burner brick

Corundum-mullite burner brick combines the advantages of corundum and mullite. Corundum gives the burner brick a higher hardness and wear resistance, enabling it to resist the erosion and wear of high-speed airflow and high-temperature particles. Mullite has good thermal shock stability, which can effectively cope with the rapid temperature changes during the heating and cooling process of the kiln, and reduce the probability of cracking and damage of the burner brick due to thermal stress. Therefore, corundum-mullite burner bricks are widely used in industrial furnaces with high requirements for thermal shock stability and wear resistance. For example, heating furnaces and heat treatment furnaces in the steel industry. Even under frequent temperature changes and high-speed airflow erosion conditions, it can still maintain good performance and have a long service life.

High-aluminum mullite burner brick

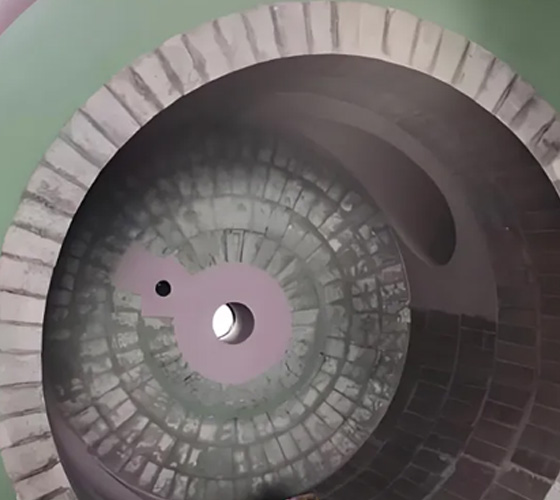

High-aluminum mullite burner bricks are mainly composed of high-aluminum raw materials and mullite. High-aluminum raw materials give it a higher refractoriness and can maintain structural stability under high temperature conditions. The addition of mullite further improves the thermal shock stability and erosion resistance of the burner brick. The burner bricks made of this material have relatively balanced performance and are suitable for a variety of industrial kilns, such as cement rotary kilns, refractory kilns, etc. Taking cement rotary kilns as an example, high-aluminum mullite burner bricks can withstand the dual erosion of high-temperature materials and flames. At the same time, they can cope with temperature fluctuations during kiln operation and provide reliable guarantee for stable combustion during cement production.

Clay burner brick

Clay burner brick is mainly made of clay and is made through molding, firing and other processes. It has relatively low cost and has certain fire resistance and thermal insulation properties. However, compared with burner bricks of other materials, clay burner bricks have relatively weak refractoriness and erosion resistance, and are suitable for some industrial kilns with low temperatures and relatively mild working conditions. For example, small brick kilns, some low-temperature drying furnaces, etc. In these kilns, clay burner bricks can meet basic use needs, and because of their cost advantages, they can reduce production costs for enterprises.

Silicon carbide burner brick

Silicon carbide burner bricks have excellent high temperature strength and thermal shock resistance. Silicon carbide materials can maintain high strength at high temperatures and are not prone to deformation and damage. Its good thermal shock resistance enables it to quickly adapt to rapid changes in temperature and reduce material damage caused by thermal stress. In addition, silicon carbide burner bricks also have high thermal conductivity, which can quickly transfer heat and improve combustion efficiency. This material of burner brick is often used in high-temperature, high-load industrial kilns. For example, hot blast furnaces in iron-making blast furnaces, nonferrous metal smelting furnaces, etc. Even under extremely high temperatures and frequent temperature changes, it can still work reliably and provide stable combustion support for industrial production.

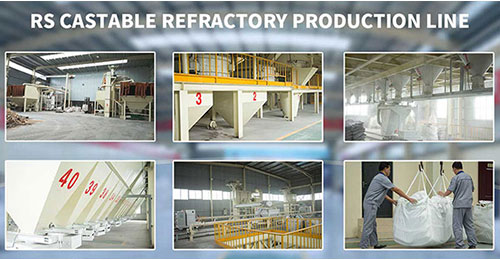

RS Refractory Manufacturer

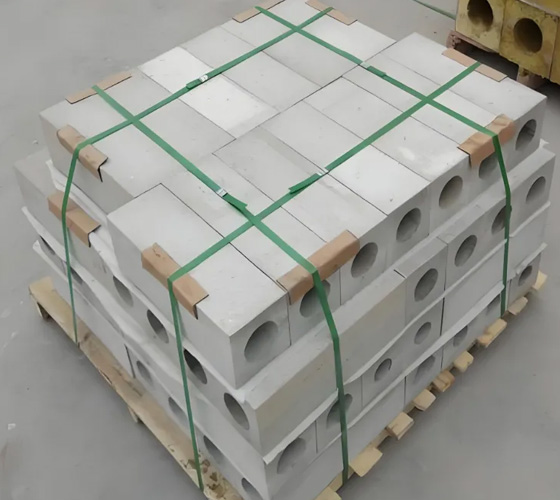

RS Refractory Manufacturer can customize refractory lining materials for high-temperature industrial furnaces. If you need high alumina refractory bricks, corundum mullite bricks, chrome corundum bricks, silicon carbide bricks, etc. Contact Rongsheng for free samples and quotes.