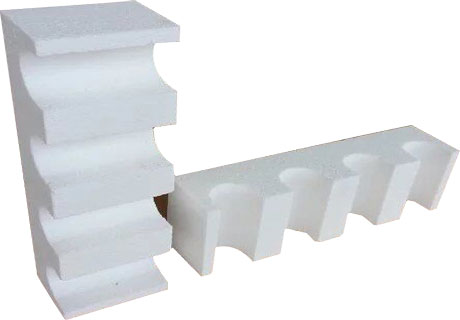

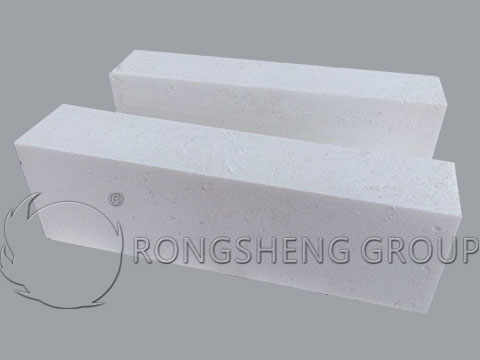

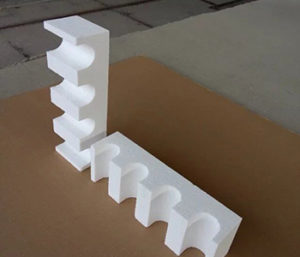

Alumina bubble brick manufacturing is made of alumina bubble as the main raw material, with high-performance corundum superfine powder as additive and organic material as binder. After molding and drying, alumina bubble brick can be fired in a high temperature furnace at 1750℃.

This series of refractory material not only has the low thermal conductivity of the insulating brick, but also has the high compressive strength, is a kind of lightweight insulating brick that can be used normally at 1700℃. Alumina bubble brick manufacturing has excellent high temperature resistance and thermal insulation performance, can be directly applied to the lining of high temperature furnace, for reducing the weight of the furnace, transformation of the structure, saving materials, saving energy, etc., have obvious effect.

In the process of production and development, we constantly optimize the structure of refractory products, stable and reliable quality. This series of refractory bricks high service temperature, high softening temperature under load, small change rate of reburning line, long service life, volume density of alumina bubble brick can reach 1.3~1.5g/cm, reasonable price concessions, significant economic benefits.

Alumina bubble brick manufacturing has obvious thermal insulation characteristics, low thermal conductivity, can play a good thermal insulation effect, thereby reducing heat emission, effectively improve the thermal efficiency, to achieve the purpose of energy saving, energy saving effect can reach more than 30%. Welcome to consult and purchase.

This series of refractory brick can be used in high temperature energy-saving invert kiln, shuttle kiln, molybdenum wire furnace, tungsten rod furnace, induction furnace, nitriding furnace, etc. For reducing the weight of the furnace body, reforming the structure, saving materials, saving energy, will achieve obvious results. We are a professional fireproof products manufacturer, experienced, high quality, welcome to purchase.