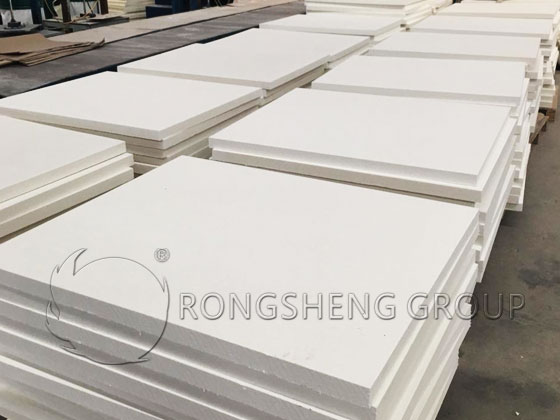

Ceramic Fiber Board for Sale, also called aluminum silicate fiberboard, is a refractory board and insulation board. Ceramic fiber board for sale can keep good mechanical strength after the heating. Compared with ceramic fiber blanket and belt, this kind of fiber insulation product has good rigidity and supporting strength. Ceramic fiber board is widely used for insulation in the kiln back lining. Any need of ceramic fiber board? Just E-mail Rongsheng Kiln Refractory Company for cheap ceramic fiber board!

Refractory Ceramic Fiber Board Introduction

The refractory ceramic fiber board is white and light which board is made by the wet vacuum forming process. The strength of the ceramic fiber board is higher than that of ceramic fiber blanket and the vacuum felt. Refractory ceramic fiber board is suitable for the high temperature field with the requirement of the rigid strength of product. In the petrochemical, metallurgical, ceramic and glass industries, ceramic fiber board is used for backing lining of the furnace.

Ceramic Fiber Board Properties

- Light weight.

- 1260℃ refractoriness.

- Low thermal capacity and low thermal conductivity.

- High pressure resistance and long service life.

- Good wind erosion resistance.

- Good thermal shock resistance.

- No expansion of heating.

- Convenient construction.

- Non brittle material with toughness.

- Accurate size and good smoothness.

- Even fiber distribution and stable performance.

- Good sound absorption and noise reduction performance.

Ceramic Fiber Board Insulation

Ceramic fiber board insulation is used for expansion joint, high temperature reaction, heating equipment, non ferrous metal industry back lining and kiln lining with the low thermal conductivity and low heat storage. Ceramic fiber board insulation is rigid refractory aluminum silica materials.

Ceramic Fiber Board Uses

- Iron And Steel Industry: used as backing heat insulation, heat insulation sheet and mold insulation in expansion joint.

- Nonferrous Metal Industry: used as backing insulation in tundish and chute cover for casting copper and copper alloys.

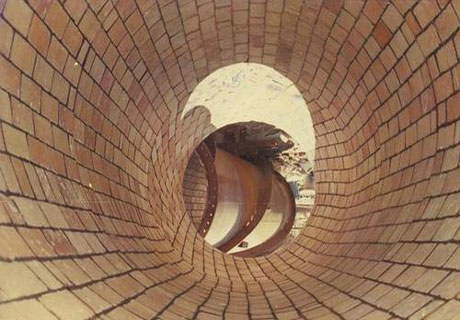

- Ceramic Industry: used as fire retaining material in light kiln car structure, like the lining of hot face of the kiln and temperature separation zone of the kiln.

- Glass Industry: used as heat insulation in the back lining of molten pool and the burner block.

- Kiln Building: used as the hot face refractory and heavy refractory in the backing and expansion joint.

- Light Industry: used for inner lining of industrial and household boiler combustor.

- Petrochemical Industry: used as the hot surface lining material in high temperature reheating furnace.

- Construction Material Industry: used as insulation board of cement rotary kiln and other heat equipment.

- Fireplace Ceramic Fiber Board: used as ceramic fiber fireproof board in wood fire door and steel fire door.

Ceramic Fiber Board Classification

- Ordinary ceramic fiber board (use temperature 1050℃)

- Standard ceramic fiber board (use temperature 1260℃).

- High purity ceramic fiber board (use temperature 1260℃).

- Alumina ceramic fiber board (use temperature 1360℃).

- Zirconium ceramic fiber board (use temperature 1430℃).

Ceramic Fiber Board Specifications

| Items | JSGW-164 | JSGW-264 | JSGW-364 | JSGW-464 | JSGW-564 |

| Temperature/℃ | 1260 | 1260 | 1260 | 1400 | 1400 |

| Change of heating permanent line/% | 1000℃, 24h

≤-3.5 |

1100℃, 24h

≤-3.0 |

1350℃, 24h

≤-3.0 |

1260℃, 24h

≤-3.0 |

1350℃, 24h

≤-3.0 |

| Thermal conductivity

W/mk |

200℃, 0.060-0.085

400℃, 0.092-0.112 600℃, 0.112-0.126 |

200℃, 0.103

400℃, 0.125 600℃, 0.151 |

|||

| Water content/% | ≤1 | ||||

| Organic matter content % | ≤5 | ||||

| Bulk density kg/cm³ | 200~400 | 200~400 | 200~400 | 240~400 | 240~400 |

| Package form | Inner plastic bag outer carton | ||||

Cheap Ceramic Fiber Board For Sale In RS Factory! Like It? Click RS!

Ceramic Fiber Board Thermal Conductivity

Because of ceramic fiber board poor thermal conductivity, traditional hot air drying process has long time consuming, high energy consumption and poor drying uniformity, while microwave drying technology is used to avoid the problem of poor heat transfer performance, improve production efficiency, meet the requirements of high efficiency, energy saving and environmental protection in modern industrial production, and solve the traditional problem of long time consuming, slow capital turnover and uneven drying. Followings are the advantages of the new drying process:

- The new drying process is quick, and complete the deep drying within a few minutes, making the final water content about 1/1000.

- The ceramic fiber board is dried uniformly with the quality of the product.

- The drying process is of high efficiency, energy saving and environmental protection.

- The thermal inertia is small, and the instantaneity of heating is easy to control.

How to Make Ceramic Fiber Board

Ceramic fiber board use spray fiber as the main material (since the spray fiber is short, fine, and easy to mix), add a certain proportion of binder and filler addictives, and is dispersed into slurry in the slurry pool through the beating machine. And then pump the slurry into forming tank and mix it with compressed air. The mould is put into the forming tank, and the fiber slurry is adheres to the mould by the vacuum pumping. Accurate control of adsorption time, vacuum dewatering, demoulding, and drying of fiber wet material for 10-24 hours. After drying, the fiberboard is precisely controlled by the special grinding machine and trimming machine.

Various Low Prcie Ceramic Fiber Board In RS Factory!Interested? Contact RS!

How to Cut Ceramic Fiber Board

Ceramic fiber board is easy to be cut into any shapes and is convenient to be installed. The best way to get a clean cut on ceramic fiber board is to use utility knife and straight edge. But when you are cutting, remember to wear a mask and cut outside. Be careful to avoid the burning fire when cutting. If you want to know the details of ceramic fiber board cutting, please email Rongsheng Ceramic Fiber Board Company.

Ceramic Fiber Board for Wood Stove

Insulation ceramic fiber board is not only commonly used in wood stove but also applied in forge, pizza oven, kiln, fireplace and heating equipment.

Buy Ceramic Fiber Board

Do you need high temperature ceramic fiber board? Do you want low density ceramic fiber board? Do you want to buy ceramic fiber board? Just email RS ceramic fiber board manufacturer! RS Kiln Company will provide you cheap ceramic fiber board! Quote Us Now!

Ceramic Fiber Board for Sale Suppliers

Rongsheng Kiln Refractory Company is a good quality ceramic fiber board supplier in China who can produce fireplace ceramic fiber board and fireproof ceramic fiber board. Any need of ceramic fiber board for the insulation of the back lining of furnace or the lining of the boiler combustor? Don’t be hesitate to email RS ceramic fiber supplier for low price! RS Refractory Company will satisfy you! RS has already sold a lot of ceramic fiber board Canada, as well as other countries, like UK, Australia, Philippine, etc. Email RS for cheap price!