With the continuous development of the economy, the precision mold and efficient mold of launch, users of the mold manufacturing requirements are increasingly high, graphite electrode as a new material, with high cutting ability, light weight, rapid molding, low expansion rate, low loss, easy to repair and other characteristics, has been widely used.

The graphite electrode material is not easy to deform during processing, and due to the characteristics of easy dressing of graphite electrode, the recessive cleaning Angle is perfectly solved when the overall common electrode is made, and the number of electrodes is greatly reduced.

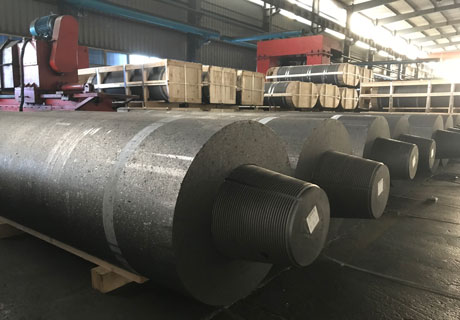

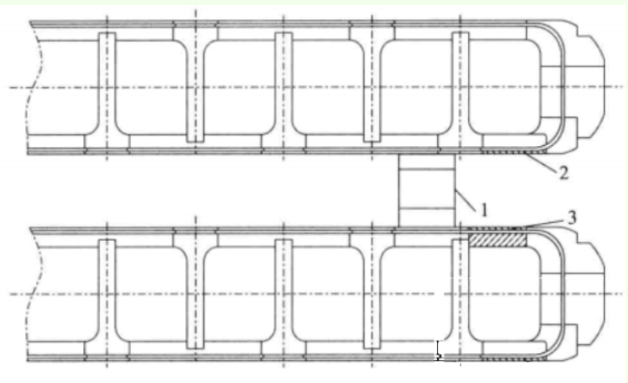

Graphite electrode will be a high-temperature graphite conductive material, the core of which consists of petroleum coke, tar coke as a filler, coal tar as a binder. It is characterized by low resistance, good electrical conductivity and thermal conductivity, high resistance to oxidation and thermal shock, high mechanical strength, etc.

It is widely used in arc furnace, resistance furnace,production of profiled graphite products and production of shaped graphite products etc.

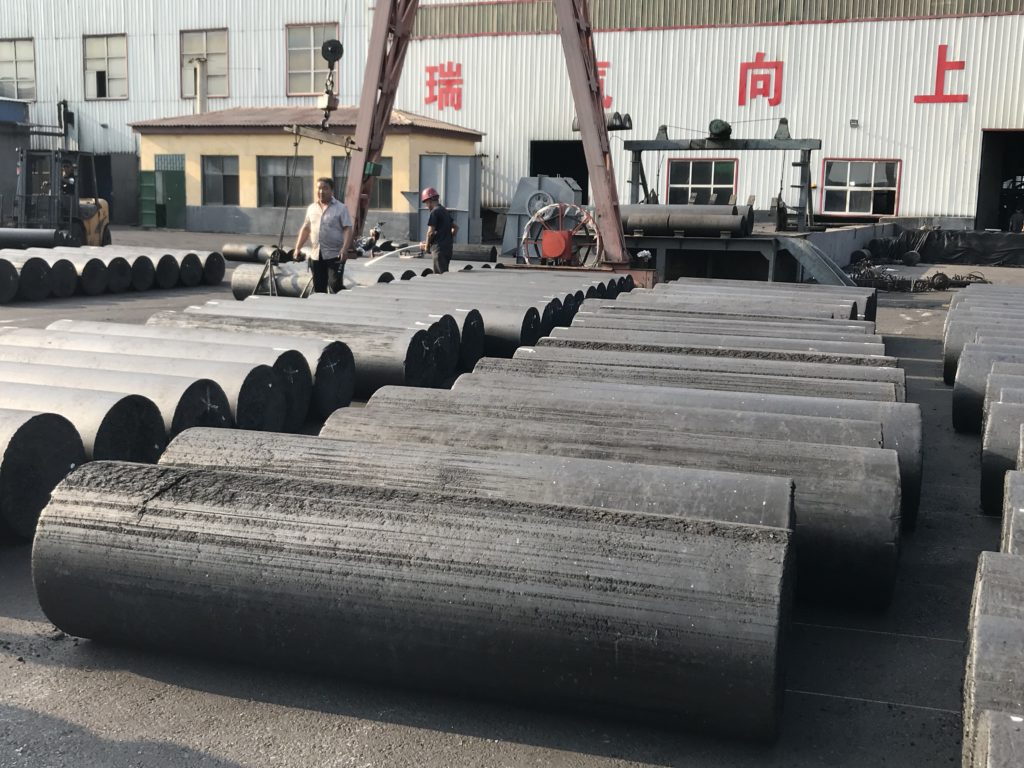

Graphite electrode with simple production process, high efficiency, small loss of graphite.High processing speed and low production cost.Available in different sizes, including large diameter and quality is very durable, long life four advantages.Welcome to consult, we will wholeheartedly provide answers for you.

We are Rongsheng Group,one of the worldwide leading manufacturers of carbon-based products.We operate close to our customers through a strong sales network and state-of-art manufacturing capacity.With this broad base,we offer best solutions to our customers with the help of our company philosophy of “Rongsheng Excellence”.