Under the erosion of flames and powder, the checker bricks in the regenerator are gradually melted into tumors, which blocks or even collapses the lattice body, reduces the heat storage capacity, and makes it difficult to discharge exhaust gas, affecting melting. At present, the regenerator checker bricks of large and medium-sized glass factories in China are mostly made of magnesia-chrome bricks, magnesia bricks, and high-quality high-purity zirconium corundum bricks with strong alkali corrosion resistance. Foreign countries use electric fused bricks to extend the life of the lattice body. However, in recent years, in order to reduce costs, the use of petroleum coke powder as fuel will have a destructive effect on the alkaline lattice body.

Thermal Repair of Heat Storage Chamber Checker Bricks

The methods of thermal repair of checker bodies are similar in various factories. Generally, the fastest one takes only 24 hours, while the slowest one takes about 48 hours. It mainly depends on the burnout of the checker body, the connection of the thermal repair method steps, and the coordination arrangement of various works.

Methods for hot repair of the air regenerator grid

The following is a method for hot repair of the air regenerator grid of the oil-fired melting furnace.

(1) Dismantle the small furnace from the slope expansion joint of the hot repair furnace, and use an oxygen melting rod to cut a 60~80mm wide incision. Prepare a fire-blocking water bag or heat-resistant steel plate to cut off the impact of the large kiln flame on the regenerator. If it is a large partition (two small furnaces and one partition wall), it is necessary to lower two insulating water bags or insulating steel plates at the same time. Lower the branch flue gate of the small furnace to be hot repaired to reduce the impact on the hot repair.

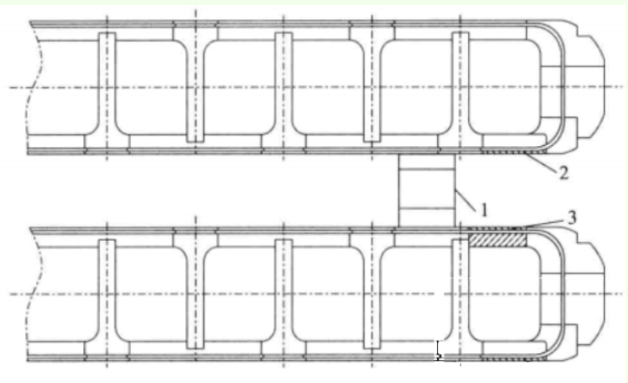

(2) Remove the insulation brick layer and door bricks of the regenerator door, insert the blocking pipe on the regenerator grate bar, cover it with an iron plate and lay it flat on the grate bar to prevent broken bricks from falling under the grate bar. The hot repair personnel use a water gun to cool the grid body, wall, etc. If the grid body and wall are made of magnesia bricks, water cooling is not allowed. Remove the bricks while beating the nodules. Pay attention to protecting the grate bar with an iron plate.

(3) After the lattice is removed, check the condition of the grate bars and clean the remaining rust with water. Only the grate bars with high alumina bricks can be watered, and other grate bars are not allowed to be flushed with water. Build the new lattice from the inside out. At the same time, you can remove the lower door of the grate bars and remove the ash. However, be careful to prevent bricks from falling and injuring people. After the lattice is built, remove the pipes, iron plates and other objects that protect the grate bars.

(4) After removing the ash, build the lower door of the grate bars and remove the gate plate of the small furnace slope water bag. Lift it up several times according to the situation. It can usually be completed within 24 hours. After blocking the door, clean up the site and the hot repair is completed. Slowly lift the gate plate of the branch flue and gradually increase the temperature to restore normal production.

Hot repair will cause pressure and temperature fluctuations in the kiln. The longer the time, the greater the impact. After the hot repair is completed and the door is sealed, the temperature in the kiln will change. The melter must be aware of it and make timely adjustments to ensure normal production of the large kiln. For interconnected regenerators, the melting and chemical workers should keep in close contact with the repair personnel during the hot repair to grasp the progress of the hot repair. Warning signs should be hung for safety reasons. When changing direction, make sure to contact first and then change the fire to avoid burn accidents.