Since carbon-free ladle bricks do not contain carbon, their thermal conductivity is lower than that of carbon-containing ladle bricks. It can reduce heat loss during the use of the ladle and the thermal impact on the cladding. According to the statistical results of the shell temperature (cladding wall part) of the carbon-free ladle brick test ladle and the normally circulating magnesium-aluminum-carbon brick ladle during use, the average shell temperature of the carbon-free ladle brick test ladle during hot repair was 22°C lower than that of the normally circulating magnesium-aluminum-carbon brick ladle, and the average shell temperature during refining was 24°C lower. This shows that carbon-free ladle bricks have better thermal insulation effects than magnesium-aluminum-carbon ladle bricks. Rongsheng Refractory Materials Manufacturer, provides high-quality ladle bricks, factory direct sales, cheap prices, and fast delivery! Contact Rongsheng for free detailed information.

What kind of refractory brick is carbon-free ladle brick?

The refractory brick matrix of the carbon-free ladle body and bottom is made of spinel and corundum, and the ladle slag line is made of low-carbon magnesium carbon brick. Spinel and corundum have high high-temperature strength, good thermal shock resistance, stable structure, and can effectively resist the stirring and scouring of molten steel. In terms of composition, a certain amount of FMgO and FAl2O3 are added to generate in-situ spinel during high-temperature use, and the volume expands slightly. The prefabricated bricks are densified, which can be used to prevent the penetration of FeO and CaO in the slag to the maximum extent, achieving better corrosion resistance and permeability resistance.

Energy-saving, efficient and environmentally friendly ladle non-fired air bricks

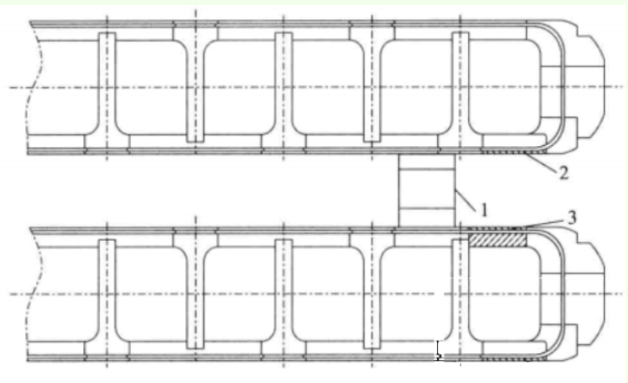

Ladle air bricks are important gas supply components for refined ladles, and play a vital role in the smelting process of grade steel and clean steel. With the development needs of off-furnace refining technology and the improvement of steel quality requirements, from the damage of refractory materials for ladles, traditional ladle air bricks can no longer meet the needs of current technological progress and production. There is an urgent need for better quality air bricks to meet the improvement of refining technology in the steelmaking process.

The development of traditional ladle air bricks is mainly divided into two stages. The first is clay dispersion air bricks, which have a very low service life due to low high-temperature strength, inability to withstand erosion of molten steel and slag erosion. The second is corundum straight-through and slit air bricks. The straight-through air bricks affect the hydrogen blowing effect due to the low repeated blowing rate, and the slit air bricks make up for the above defects. It has the characteristics of large ventilation volume, good stirring effect, high repeated blowing rate, and good high-temperature performance. However, the slag resistance and thermal shock resistance of corundum castables are not ideal, which affects the anti-slag erosion and penetration performance of the air bricks under hot working conditions, making it impossible for the corundum air bricks to achieve synchronous service life improvement with the ladle.

Unfired corundum spinel carbon-free ladle brick

In view of the shortcomings of the above mentioned technologies, the unfired corundum-spinel air brick for the ladle can solve the above-mentioned problems. Thus, one of the brick types of carbon-free ladle bricks was born.

The air brick uses high-purity fused and sintered corundum, pure calcium aluminate cement, alumina micro-powde,r and high-efficiency polycarboxylic acid dispersant as the main raw materials. Adding 15%~30% of fused magnesium aluminum spinel fine powder can greatly improve the erosion and permeability of the air brick against slag, and the erosion depth of the slag can be very small. At the same time, the reasonable application of high-performance polycarboxylic acid dispersant can enable the air brick to achieve the necessary operating performance during production while minimizing the amount of water required for its molding. It is beneficial for reducing the porosity of the air brick and improving its overall density and high-temperature hot flexural strength. In addition, since ordinary ladle air bricks need a high-temperature firing process when they are produced in the factory to ensure that the air bricks have good strength and performance. The unfired corundum-spinel air brick still has the performance of ordinary high-temperature fired air bricks without high-temperature firing. It can not only meet the needs of steelmaking and smelting production, but also reduce the consumption of natural gas and other energy sources, save energy and protect the environment, and has broad application prospects.

Application advantages of unburned corundum-spinel carbon-free steel ladle bricks

(1) Unburned corundum-spinel carbon-free steel-ladle bricks have advantages such as good physical properties and anti-scouring properties, can meet the requirements of on-site use, and have better application prospects.

(2) Unburned corundum-spinel carbon-free steel-ladle bricks do not use phenolic resin as a binder but use complex magnesium aluminum sol as a binder. The baking process is smokeless and non-toxic, and it is an ideal environmentally friendly binder.