High alumina refractory castable is a kind of refractory castable which is made of high alumina as aggregate and powder and joined with binder.The castable has high mechanical strength and good thermal shock and corrosion resistance. It is widely used in lining of boiler, blast furnace, heating furnace, ceramic kiln and so on.

This type of refractory castable has good plasticity and convenient construction, strong bonding strength, strong corrosion resistance, high fire resistance, good slag penetration resistance, good

thermal spalling property.

It in the process of use, water consumption should be strictly controlled to avoid affecting the use effect after pouring.And should be produced according to the required amount, the finished castable should be used up within 30 minutes.Determine the pouring thickness according to the design, do not randomly pour, and pay attention to the heating rate and time after baking.

High alumina refractory castable is synthesized in a certain ratio. With high temperature performance, high resistance, no shrinkage, wear resistance and other characteristics. Most of them are used in industries such as hardware, smelting, chemical industry and non-ferrous metals, especially in the iron and steel industry, it is used in front kiln mouth, disintegration furnace, kiln head cover and so on.

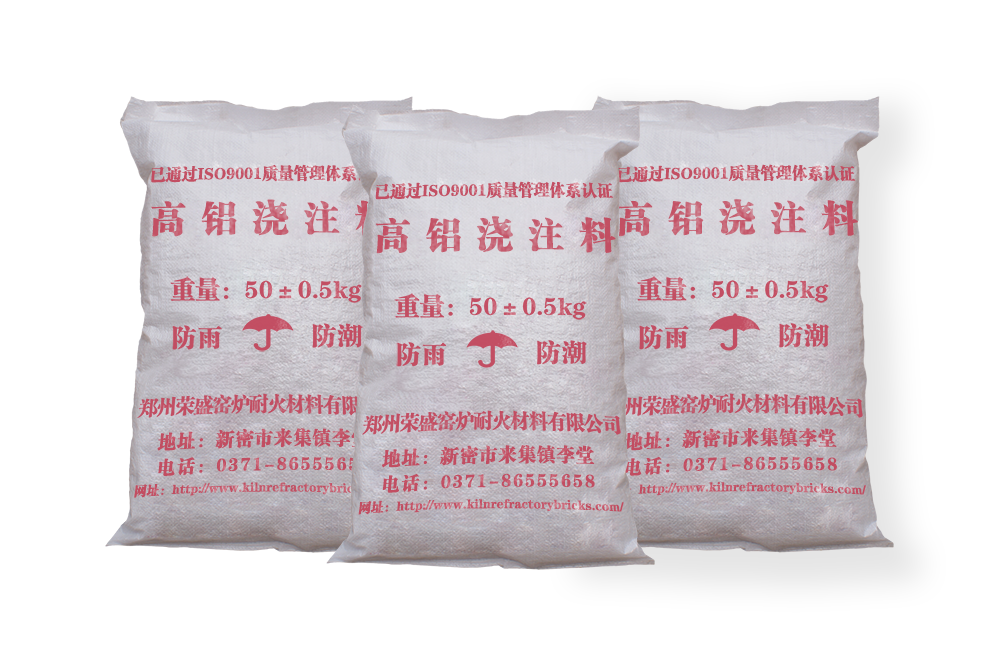

We are professional high alumina refractory castable manufacturer and supplier. Our product has been through professional certification, the product will be checked before shipment, on-time delivery under the promise to ensure that give you bring high quality products.