Fire Clay Bricks For Sale are made of clay clinker and refractory clay. The alumina content of the fire clay bricks for sale is 30%~40%. Fire clay bricks are used in civil and architectural engineering. If you want high quality fire clay bricks for sale, please E-mail RS Fire Clay Bricks Company! Rongsheng Refractory Company will offer you qualified fire clay bricks for sale with low price! Interested? Contact RS!

What Is Fire Clay Bricks For Sale

Fire clay bricks for sale are refractory clay bricks with 30~48% Al2O3 content and 50~65% SiO2 content, the refractoriness will increase with the increase of the ratio Al2O3/SiO2. Fire clay bricks for sale use clay clinker as aggregate and refractory clay as binder, forming by semi dry method. Fire clay bricks for sale are building materials in China’s five thousand years of history and are favored by Chinese engineers. Fire clay bricks for sale are acid refractories which are widely used in acid kiln lining with long life service.

Fire Clay Bricks Properties

- Al2O3 content 30~48%, SiO2 50~65%.

- Refractoriness is around 1580~1750℃.

- RUL is between 1250~1450℃.

- Low thermal conductivity.

- Low coefficient of linear expansion.

- Good thermal shock resistance.

- Good acid slag resistance.

- Fire protection.

- Heat and sound insulation.

- Moisture absorption.

Fire Clay Bricks For Sale Varieties

- Fire clay bricks for blast furnace.

- Fire clay bricks for hot-blast stove.

- Large fire clay bricks for glass kiln.

Fire Clay Bricks Uses

Fire clay bricks belong to acid refractory products, and the acidity of fire clay brick increases with the increase of silica content. The fire clay bricks have a certain anti erosion ability for acid slag, but the resistance to alkaline slag erosion is weak, so the fire clay bricks are suitable for the lining of acid furnace. Fire clay bricks are also used in blast furnace, hot blast stove, glass kiln, carbon baking furnace and other high temperature equipment.

Fire Clay Bricks For Blast Furnace

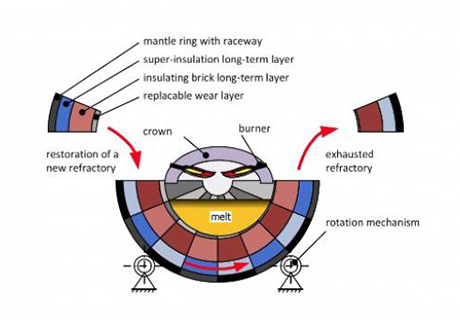

Fire clay bricks for blast furnace lining are clay bricks produced by refractory clay. The fire clay bricks used for blast furnace are used for the throat, the body, the hearth, the bottom of the small blast furnace lining and large blast furnace body.

The fire clay bricks used in blast furnace requires high refractoriness at normal temperature and can withstand long-term operation wear of furnace material. The small volume shrinkage of the furnace at the high temperature is beneficial to the integrity of the furnace lining. The low apparent porosity and low Fe2O3 content can reduce the deposition of carbon in the pores in order to avoid the expansion and porosity of fire clay bricks in the process of use, reducing the formation of low melting points. Fire clay bricks for blast furnace has better performance than common clay brick.

Fire Clay Bricks For Hot Blast Stove

Fire clay bricks for hot blast stove are bricks made of refractory clay for the masonry of BF hot stove. Fire clay bricks for hot blast stove are also applied in checker chamber and partition wall. The fire clay bricks used in hot blast stove should have good thermal shock resistance, high refractoriness under load and small creep.

Fire Clay Bricks For Glass Kiln

The large fire clay bricks for glass kiln are used for the building of glass kiln with the piece weight no more than 50kg.

Fire Clay Bricks Manufacturing Process

Kaolinite and 6~7% potassium, sodium, calcium, titanium and iron oxides impurities are the main mineral composition of fire clay bricks. The burning process of the fire clay bricks is the continuous dehydration of kaolinite(Al2O3.2SiO2.2H2O) and the crystallization of mullite(3Al2O3.2SiO2). Eutectic and low melting silicate are formed by SiO2 and Al2O3 during the sintering process of fire clay bricks, surrounded by mullite crystals.

The fire clay bricks manufacturing process are divided into four steps:

- The preparation of clay clinker.

Clay clinker is calcined from hard clay in a rotary kiln, or soft clay made into a ball in advance, and then burned into brick, playing a skeleton role in the fire clay brick. The fire clay bricks require the clay clinker has stable chemical composition, low impurity content, good sintering, 2~4% water absorption, and 2.7g/cm³true density.

- The selection of plastic clay and clay binder.

The plastic clay should be of high plasticity, high heat resistance and low sintering. Usually use semi soft clay and soft clay composites as raw materials. The particle size of plastic clay generally requires to be less than 0.5mm. In practical production, 1~2% sulfite pulp waste liquid binder is often added.

Cheap Fire Clay Bricks For Sale In RS Factory! Interested? Contact RS!

- The preparation of granular clay.

The matching of clay clinker and and plastic clay is determined by the quality, shape, size and forming method of fire clay bricks. When the quality requirements are high, clay clinker content is 80%~90% which can produce high density, high strength and the right size refractory products. For some special-shaped products, the average amount of plastic clay added is 25%~30%, sometimes up to 40%. In the particle composition of clay products, there are more coarse particles than medium particles which guarantee the density and strength of the fire clay bricks and improve the thermal shock resistance of the fire clay bricks.

When mixing the materials, clinker coarse particles are add first and then raw mud, and clinker fines and plastic clay are finally added.

- Drying and firing process.

Fire clay bricks are usually formed by semi-dry method. In the process of firing fire clay bricks, a series of physical and chemical reactions are set of in the high temperature and suitable atmosphere.

Qualified Fire Clay Bricks For Sale In RS Factory! Interested? Click RS!

Fire Clay Bricks Index

| Index/ Item | N-1 | N-2a | N-2b | N-3a | N-3b | N-4 | N-5 | N-6 |

| Refractoriness/℃≥ | 1750 | 1730 | 1730 | 1710 | 1710 | 1690 | 1670 | 1580 |

| Apparent porosity/% ≤ | 22 | 24 | 26 | 24 | 26 | 24 | 26 | 28 |

| 0.2MPa RUL/℃ ≥ | 1400 | 1350 | 1320 | 1300 | ||||

| Cold crushing strength/MPa ≥ | 30 | 25 | 20 | 20 | 15 | 20 | 15 | 15 |

| Reheating linear change rate/% | -0.4~0.1

1400℃ 2h |

-0.5~0.1

1400℃ 2h |

-0.5~0.2

1400℃2h |

-0.5~0.2

1350℃ 2h |

-0.5~0.2

1350℃ 2h |

-0.5~0.2

1350℃ 2h |

-0.5~0.2

1350℃ 2h |

Fire Clay Bricks Suppliers

Rongsheng Kiln Refractory Company is a one of the most professional fire clay bricks suppliers in the world with the advanced fire clay bricks production equipment and production line. RS fire clay bricks supplier produces a large amount of fire clay bricks annually and sells them remotely to South Africa countries, like India. If you want to buy high quality fire clay bricks for your blast furnace, just email RS fire clay bricks supplier! Buy Cheap Fire Clay Bricks From RS Fire Clay Bricks Supplier!