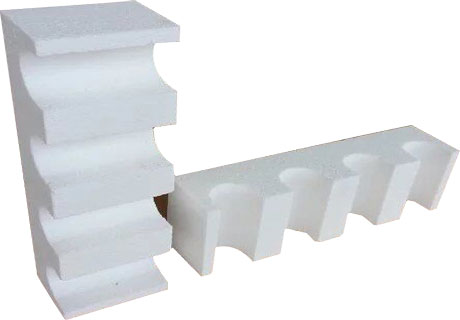

Alumina Bubble Bricks is a heat-insulating refractory product made of alumina hollow balls as the main raw material. It is mainly used as the lining of high-temperature industrial furnaces below 1800℃ and the thermal insulation layer of high-temperature thermal equipment. Rongsheng refractory material manufacturer can provide high-quality high-temperature refractory lining material products for high-temperature industrial furnaces, including various refractory bricks, amorphous refractory castables, etc. Contact Rongsheng for free samples and quotes.

Rongsheng High-Temperature Alumina Bubble Bricks

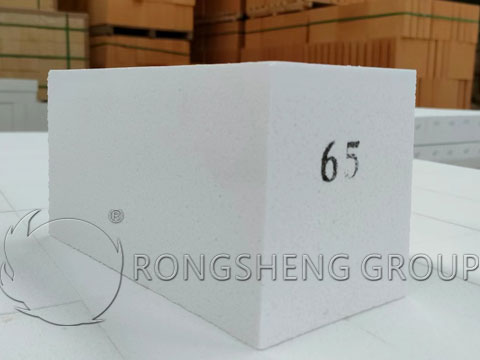

The aluminum content of Alumina Bubble Bricks is not less than 98%, the SiO2 content is not more than 0.5%, and the Fe2O3 content is not more than 0.2%. The volume density is 1.3~1.4g/cm3, and the apparent porosity is 60~70%. The compressive strength is not less than 9.8MPa, and the softening temperature under load (0.2MPa) is not less than 1700℃. The thermal conductivity is 0.7~0.8W/(m.k).

The Production Process of Alumina Bubble Bricks

Alumina bubble bricks are heat-insulating refractory products made of hollow alumina balls as the main raw materials.

To manufacture Alumina Bubble Bricks, first prepare hollow alumina balls and then make hollow alumina bricks. Add the alumina raw material into a tilting electric furnace and melt it into a liquid state. Then tilt the furnace at a certain angle to allow the solution to flow out of the casting trough at a certain speed. The liquid flow is blown away by a high-speed airflow at a pressure of 0.6~0.8MPa through a flat nozzle at an angle of 60~90° to the flow stream, thus forming hollow alumina balls. Then, the hollow alumina balls, sintered alumina fine powder and binder are mixed in a certain proportion, formed, dried, and fired to obtain Alumina Bubble Bricks.

Alumina hollow balls are made from industrial alumina as raw material, which is melted by electric melting and then sprayed. The electric melting equipment is an electric arc furnace. The molten pool is made of graphite products or other refractory materials, a flow port is built on the edge, and a compressed air nozzle is installed on the outside of the flow port, and the nozzle is connected to the compressed air device by a pipe. The furnace body can be tilted; the electrode is a graphite electrode product.

After adding industrial alumina powder into the molten pool, it can be melted by electricity. When the molten liquid temperature reaches or exceeds 2200℃, the molten liquid rolls, that is, the furnace body is tilted to make the molten liquid flow out, and the molten liquid stream is sprayed with compressed air. Due to the viscosity and surface tension of the molten liquid, the molten liquid forms hollow balls wrapped in air during the spraying and condensation process. After collection and screening, they are stored separately according to different particles for standby use.

The number ratio of alumina hollow balls of different particle sizes varies with the different compressed air spraying pressures. The greater the pressure, the more small balls there are.

The wall thickness of the hollow ball varies with the particle size. When the particle size fluctuates within the range of 5 to 0.5 mm, the wall thickness fluctuates within the range of 0.3 to 0.1 mm accordingly.

The larger the particle size of the hollow ball, the smaller its natural bulk density. The smaller the particle size, the greater its natural bulk density. For example: when the particle size is 5.13-3.22mm, the natural bulk density is 470g/L. When it is 3.22-2.0mm, it is 670g/L. When it is 2.0-1.0mm, it is 810g/L. When it is 1.0-0.5mm, it is 915g/L.

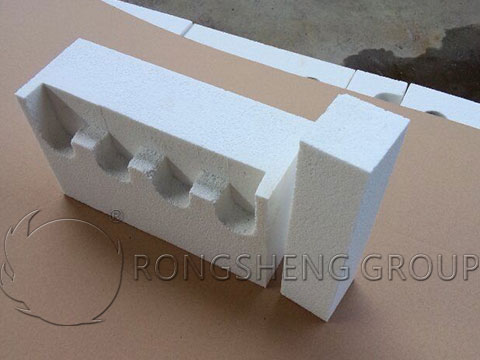

The manufacture of Alumina Bubble Bricks requires the alumina hollow balls, sintered alumina fine powder and binder to be mixed, formed, dried and fired in a certain proportion to finally obtain Alumina Bubble Bricks.

- Alumina fine powder is made of industrial alumina as raw material, calcined at 1500℃, ground, pickled and dried.

- The binder used for brick making is usually an aqueous solution of aluminum sulfate or an aqueous solution of aluminum dihydrogen phosphate.

- The particle size of hollow alumina spheres is generally 5-0.5 mm, and the dosage is 65%-70%. The dosage of alumina fine powder is 30%-35%, and the dosage of binder is 5%.

The above materials are mixed evenly, formed by vibration molding, and the bricks are dried and fired at 1500-1800℃ to obtain fired bricks. Unfired products can also be obtained without firing, or furnace linings can be directly constructed with amorphous materials.

Application of Rongsheng Alumina Bubble Bricks

Rongsheng Alumina Bubble Bricks are mainly used as the lining of high-temperature industrial kilns below 1800℃. For example, high-temperature kiln lining bricks in refractory materials, electronics, and ceramic industries. The thermal insulation layer of high-temperature thermal equipment, such as petrochemical industry gasification furnaces, gasification furnaces, carbon black industrial reactors, and insulation bricks for metallurgical industry induction furnaces. Application in the above fields can save energy by 20% to 30%. This brick is used as the lining of high-temperature kilns. The heating speed during baking cannot be too fast, otherwise, cracks will occur, reducing strength and service life. Because of its high apparent porosity, it cannot be used in areas that contact with slag, otherwise, it will be damaged by the penetration of slag.

To purchase high-quality Alumina Bubble Bricks, high-temperature kiln insulation bricks, and high-temperature kiln insulation materials, please contact the Rongsheng refractory material manufacturer.