Monolithic Refractory is a kind of refractory material in amorphous form. Made up by the mixture of refractory aggregate, monolithic refractory powder, binder and admixture, monolithic refractory includes castable refractory, plastic refractory, ramming mass refractory, casting refractory, refractory mortar and refractory coating. Such refractory material is monolithic refractory which is used for the eamless structures construction. Any need of any kind of monolithic refractory, just Email Rongsheng Kiln Refractory Company.

Monolithic Refractory Definition

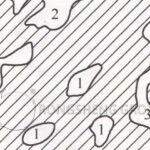

Monolithic refractory, made up of refractory granular aggregate, powder, and binding agent, is a bulk refractory that can be burnt into use without forming. Monolithic refractory can be made into slurry, mortar, and scattered shapes which are widely applied in the lining of heating equipment. Compared with shaped refractory bricks, monolithic refractory has the advantages of simple manufacturing process, energy saving, low cost, mechanized construction, etc, processing the good results on the heat equipment than refractory bricks.

Monolithic Refractory Uses

Monolithic refractory can be used to replace or repair the partially damaged brick masonry or structure rapidly and economically. Monolithic refractory can also be used for the protective layer, joint material and lining of various kilns due to the easy construction of monolithic refractory.

For example, monolithic refractory is mainly used in the irregular shape or the deformation part of the new dry cement kiln body, such as the preheating system, the kiln tail, the kiln head, the coal nozzle, the three wind pipe, the cooling machine and the residual heat generator.

Monolithic Refractory Properties

- Simple construction and strong adaptability.

- High thermal resistance and low hot consumption.

- Good integrity, and air tightness.

- Good comprehensive using effect.

- High labor productivity and short production cycle.

Monolithic Refractory Type

- Monolithic Refractory Castable

Monolithic refractory castable is dry mixture refractory material. During the construction, the mixture is mixed with liquid, which can coagulate and harden after forming for a while, thus endowing the material with certain structural strength.The monolithic refractory castable can be divided into vibrating castable, self-flowing castable and pump castable.

Monolithic refractory castable has good fluidity with the mixture of water. The construction methods of monolithic refractory castable include vibration method, pump injection method, pressure injection method and injection method. Monolithic refractory castable is often used in combination with metal or ceramic anchors. If added with stainless steel fiber, it can improve its resistance to mechanical vibration and thermal shock resistance. The monolithic refractory castable material is used as the lining of different heat treatment furnaces, ore roaster, catalytic cracking furnace and conversion furnace, as well as the lining of melting furnace and high temperature melt tank, such as lead and zinc melting furnace, tin trough, salt bath furnace, tapping or iron trough, steel bucket, steel vacuum cycle degasser suction nozzle and so on.

- Monolithic Refractory Ramming Mass.

Monolithic refractory ramming mass is a semi wet or wet refractory mixture with non plasticity or low plasticity and is constructed by ramming. After construction, monolithic refractory ramming mass is hardened by heating and burning with certain structural strength.

- Monolithic Refractory Plastic.

Monolithic refractory plastic has certain plasticity and is constructed by tamping or spraying. After construction, Monolithic refractory plastic has certain structural strength after natural drying and heat baking. Monolithic refractory plastic material must be added with plastic clay, or some organic plasticizers.

- Monolithic Refractory Gunning Mix.

The monolithic refractory gunning mix material is sprayed by a dedicated gunning machine with high-speed airflow as the carrier. The spraying methods are divided into three types: wet method, dry method, and flame method. According to the state of the receiving surface of the material, it is divided into two types: cold material spraying method and molten material spraying method.

- Monolithic Refractory Coating.

Monolithic refractory coating is a paste or mud – like refractory mixture. Monolithic refractory coating can be shelled out or coated artificially, and can also be constructed by mechanical spraying or pouring method. Generally monolithic refractory coating is used as joint material or filler material for firebrick masonry. Like monolithic refractory mortar, monolithic refractory coating can be used as fireproof lining protection layer and working layer.

- Monolithic Refractory Press-in.

The monolithic refractory press-in mixture is extruded or pressed by special extruder or pressure injection machine. Monolithic refractory press-in is divided into hard extrusion material and soft filter. Hard extruding material is plastic material, such as blast furnace mud, hot extrusion material of blast furnace and soft pressure grouting material like viscoplastic mortar, which is used as filling material between masonry of refractory products or between refractory product masonry and furnace shell.

- Monolithic Refractory Casting.

Monolithic refractory casting mixture is cast artificially or mechanically. For example, the large area repair of the converter lining is made of magnesia carbon hot patching material and hot patching material at the bottom of electric furnace, as well as the siliceous ladle projecting material.

- Monolithic Refractory Dry Vibrating.

Monolithic refractory dry vibrating is a dry refractory mixture without liquid blender. Monolithic refractory dry vibrating can be directly filled in the gap between the mold tire and the liner shell in construction, or filled in a refractory liner flow mouth.

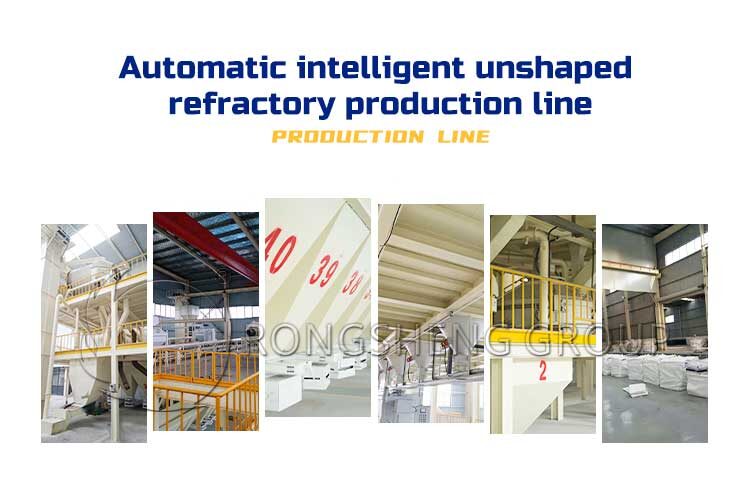

Monolithic Refractory Manufacturer

As a professional monolithic refractory manufacturer, Rongsheng Kiln Refractory Company can produce various high quality monolithic refractory for different uses. If you are going to buy monolithic refractory materials to repair the lining of your furnace, kiln, or other heat equipment, contact RS company! If you need the monolithic refractory for the masonry of the work layer and protection layer of lining, Email RS Now! RS monolithic refractory manufacturer will offer you the satisfied monolithic refractory materials with low price and good monolithic refractory service!