Refractory Cement For Sale, whose refractoriness is higher than 1580℃, is widely used in building construction and metallurgical blast furnace. Refractory Cement for sale, like aluminate refractory cement, low lime aluminate refractory refractory cement and calcium magnesium aluminate cement are the raw materials for making refractory concrete. If you want to buy cheap Refractory Cement for sale for your forge, pizza oven or blast furnace, please contact Rongsheng Kiln Refractory Company! RS Kiln Refractory Company will offer you the high quality refractory cement.

What Is Refractory Cement For Sale

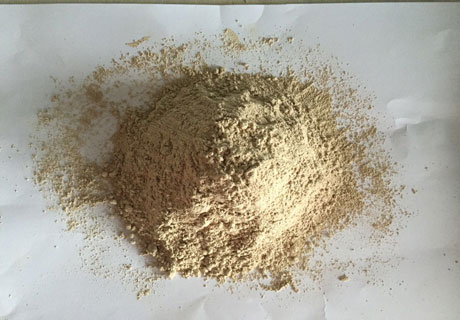

The refractory cement for sale, or furnace cement, use a certain proportion of high quality bauxite and high quality lime as raw materials and get clinker with aluminate after sintering. And then ground the clinker with aluminate into fine powder, the hydraulic cementitous material with heat resistance is refractory cement. Refractory cement for sale is a cement with special materials used in the preparation of high temperature concrete.

Application Of Refractory Cement For Sale

Refractory cement for sale can be used to cement a variety of refractory aggregates, such as corundum, Calcined Bauxite, etc., to make refractory mortar or concrete. Refractory cement material is used for cement rotary kiln and other industrial furnaces as lining. The refractory cement for sale can also be used in high temperature projects which are eroded by atmospheric and rain water for a long time. In brief, refractory cement material is used in petroleum, metallurgy, chemical, electric and building industries.

Properties Of Refractory Cement For Sale

- Easy construction.

- Good thermal shock resistance.

- Good acid corrosion resistance.

- Good wear resistance.

- Anti stripping.

Classification Of Refractory Cement For Sale

According to the composition of refractory cement, it can be devided into the following four kinds.

Low Calcium Aluminate Refractory Cement

Low calcium aluminate refractory cement is made of appropriate proportions of high quality bauxite and limestone by sintering and grinding. Refractory cement along with refractory aggregate (calcined bauxite and high alumina fragmentation) whose refractoriness is above 1770℃ consists of the refractory concrete and refractory mortar. Low calcium aluminate refractory cement has low early strength and high refractoriness. The low calcium alumina cement has goog performance like good acid resistance, high strength and wear resistance, high mechanical strength, good thermal shock resistance, high temperature resistance and good erosion resistance.

Aluminate Refractory Cement

Aluminate refractory cement is a kind of refractory cement, which is made up of 4 portions of low calcium aluminate refractory cement clinker and 1 high alumina cement clinker. Aluminate refractory cement has high early strength (quick setting and hardening rate), high refractoriness and good sulphate corrosion resistance and is especially suitable for refractory brick masonry building with difficult structure. Nowadays, aluminate refractory cement is widely used in emergency projects, like national defense, road repair and special project.

Calcium Magnesium Aluminate Cement

Calcium magnesium aluminate cement is an aluminate cement made of high quality bauxite and dolomite in proper proportions by sintering and grounding. The refractoriness is above 1650℃. The calcium magnesium aluminate cement has strong chemical erosion resistance of slag and molten metal. Compared with low calcium aluminate refractory cement: the mixing water is less; the porosity after cement hardening is lower; and the calcination shrinkage is small.

Dolomite Refractory Cement

Dolomite refractory cement is made of dolomite as the main raw material, with apatite and iron ore.

Specifications Of Refractory Cement For Sale

Low lime aluminate refractory cement

| Components | Al2O3 | CaO | SiO2 | Fe2O3 |

| Percentage | 70% | 19~23% | <4% | <1.5% |

Aluminate refractory cement

| Components | Al2O3 | SiO2 | Fe2O3 |

| Percentage | 50% | ≤10% | ≤3% |

Calcium magnesium aluminate refractory cement

| Components | Al2O3 | CaO | MgO | SiO2 & Fe2O3 |

| Percentage | 66~74% | 13~18% | 10~13% | little |

Portland refractory cement

| Components | Al2O3 | CaO | SiO2 | Fe2O3 |

| Percentage | 3~8% | 60~67% | 17~25% | ≤6% |

Various Refractory Cement For Sale In RS Factory! Interested? Click RS!

Attentions To Refractory Cement Recipe

When making and using refractory cement, the users should pay attention to the following things.

- Under the temperature of 350℃, it is most likely to cause partial bursting and special attention should be paid to slow baking. If there is still a large amount of steam coming out after holding at 350 C, the heating rate should still be slowed down.

- Under the condition of poor ventilation and difficult drainage of water and gas, it is necessary to extend the holding time accordingly.

- When baking with heavy oil, it is necessary to prevent heavy oil from spraying on the lining surface so as to prevent local bursting.

- When baking with wood, the direct contact with the flame often causes the rapid heating up.

- It needs at least 3 days before the new refractory cement is baked.

- The cooling process of refractory cement lining should also slow down in order to avoid positive ventilation.

Refractory Cement For Sale For Forge

If you don’t know where to buy refractory cement for forge lining, come and find Rongsheng Kiln Refractory Company. Rongsheng Refractory Company has various kinds of refractory cement, such as aluminate refractory cement, low lime aluminate refractory cement, calcium magnesium aluminate cement, dolomite refractory cement, and special refractory cement for your forge. RS refractory cement manufacturer can also provide you the usage method of the refractory cement and the good after sales service. Where to get refractory cement? Find Rongsheng Refractory Company!

Cheap Refractory Cement For Sale In RS Factory! Any Need? Quote RS!

Refractory Cement For Sale For Pizza Oven

Refractory cement, especially refractory insulating cement is always used for pizza oven dome building. The refractory insulating cement is used to conserve heat energy and reduce the consumption of fuel, for it has low density and thermal conductivity. And refractory castable cement is also applied in the pizza oven domes to filled the gaps.

To make refractory cement for sale needed for wood pizza oven building, followings are the raw materials.

- 120kg refractory cement(one refractory cement bag is 40kg)

- 20kg hydrated lime

- 20kg fire clay

- 0.5-0.75mm plasterer sand

- 0.1-0.2m³vermiculite

- 200kg medium pumice

How To Make Refractory Cement

How to make refractory cement? If you want to diy refractory cement, Rongsheng Kiln Refractory Company can offer you the refractory cement recipe and teach you how to make refractory cement in details. Rongsheng refractory factory has the advanced technology and equipment to make refractory cement as well as the quality monitoring system.

Refractory Cement Suppliers

Any need of cheap refractory cement powder? Please Email Rongsheng Kiln Refractory Company to get the quote! Rongsheng Refractory Company, as a good refractory cement supplier, sells high quality refractory cement remotely to UK, Australia, Canada, etc. Quote RS Company for the best price!