Wear-resistant amorphous materials include wear-resistant plastics, fire-resistant wear-resistant plastics, corundum wear-resistant plastics, and corundum wear-resistant plastics. These types of plastics have different raw material configurations, different use parts, and different use temperatures. The Application of Wear-Resistant Refractory Plastic in CFB Boiler Lining from Rongsheng refractories materials manufacturer.

Wear-resistant plastic

Wear-resistant plastic is a high-alumina, corundum granular product. Compared with traditional refractory plastics, it has the advantages of simple construction, good efficiency, good molding and high strength. The material is composed of adhesive, refractory aggregate and hardening agent, and is a plastic refractory clay formed by adding a certain proportion of PA glue. It is convenient for the construction of various complex parts. It is a gas-hardening material with low-temperature hardening properties, which is required to ensure the wear resistance of circulating fluidized bed boilers. Wear resistance is poor.

1) How to use

Use a forced mixer to mix. When stirring, add the coagulant evenly, after dry stirring for 1 minute, add 4-5% adhesive and stir for 3 minutes. When the material has a certain plasticity, it can be unloaded for use.

Using rubber hammer ramming construction or machine ramming construction, the construction time can be guaranteed after 30 minutes, and the initial setting time is about 1 hour.

During construction, lay the plastic to a certain thickness, generally no more than 60mm thick. If the construction is interrupted, the ramming surface should be tightly covered with plastic cloth to prevent rapid drying. The construction time of the wear-resistant plastic after stirring is about 30 minutes (it will vary with the ambient temperature). Once it has hardened for too long, it should be thrown away and cannot be used further.

2) Applicable area

It has a wide range of applications, and the materials and binders used can be selected according to the conditions of use. It can be directly cast into a lining body, or can be used as a prefabricated block by casting or shaking.

Suitable for high temperature areas with low friction. Such as the bottom air chamber of the boiler, the primary air duct, the return material riser (feed leg), the return material device, the return material pipe, the tail flue furnace wall, the slag cooler, and the filling of the furnace doors of the tail flue, etc.

3) Storage method

Generally stored in a cool and dark place, the shelf life is about 2 to 3 months.

Fire-resistant and wear-resistant plastic

Wear-resistant refractory plastics are made of high alumina bauxite clinker, corundum, mullite and silicon carbide as aggregates. Has excellent wear resistance, super adhesion and high service temperature. A refractory material with high strength and wear resistance formulated with different binders and admixtures. It has the advantages of convenient construction, good plasticity and good wear resistance. The wear-resistant layer after construction has high strength and wear resistance, which can fully meet the performance requirements of wear-resistant refractory materials for boilers.

1) How to use

The materials and binders are mixed with phosphoric acid and used evenly, and the ramming process is usually used for construction.

2) Applicable area

It is suitable for the construction of parts with thin thickness such as the water wall of the furnace, and is mainly used in the dense phase area of the furnace and the parts such as steam-cooled and water-cooled cyclone separators. The wear-resistant refractory material in this area is designed as a single-layer ramming structure and is fixed with wear-resistant pins. Its design thickness is relatively thin, and it is directly laid on the construction surface.

Application in repairing circulating fluidized bed cyclones. Its superior bonding properties can repair any irregular wear parts at will without the use of steel templates or molds. After the construction is completed, it can be ignited immediately without special maintenance, thereby shortening the construction period and saving costs.

3) Storage method

Avoid storage in the open air and prevent direct sunlight. It should be stored in a cool and humid place in summer and frost-proof in winter.

Corundum wear-resistant refractory plastic

It belongs to the field of high temperature wear-resistant refractory materials. The raw materials are composed of high-alumina homogeneous material, alumina micro powder, silica micro powder, clay, phosphoric acid, aluminum dihydrogen phosphate solution and pure calcium aluminate cement. It is characterized by the use of synthetic homogeneous materials with low water absorption, low porosity and high uniformity to replace the traditional natural raw material or corundum composite raw material system of sintered bauxite clinker with high water absorption, high porosity and poor uniformity. A homogeneous corundum high-strength wear-resistant plastic refractory is produced.

1) How to use

This material adopts the construction process of ramming, which is suitable for the construction of thin parts such as the water wall of the furnace. The wear-resistant layer after construction has high strength and wear resistance. Different from the castable, the plastic does not need to support the mold, and directly adopts the construction method of smearing and ramming. The material has good construction performance, high strength, good wear resistance, and has the best field use effect, which is beneficial to prolong the service life of the furnace lining and improve the utilization efficiency of high temperature kilns.

2) Applicable area

Mainly used in the dense phase zone of the furnace and steam-cooled / water-cooled / adiabatic cyclone separators and other parts. The wear-resistant refractory material in this area is designed as a single-layer ramming structure, which is fixed by wear-resistant pins. It needs to be laid directly on the construction surface.

Silicon carbide corundum wear-resistant refractory plastic

This material is a high-grade refractory material, which has excellent wear resistance, super adhesion and high service temperature, and is famous for its simple construction process, short construction period, and no need for an oven after construction. After practice, its service life is significantly higher than that of other wear-resistant refractory materials, and it is widely used in electric power, metallurgy, steel, ceramics and other industries.

1) How to use

This material is constructed by smearing, ramming and compacting. Before construction, the rigid anchoring nail tip should be fixed in the required position, and the upper, lower, left, and right mesh interval of the anchoring nail tip should be about 120-150mm (maximum should not exceed 200mm). During construction, the plastic can be laid on the required parts and evenly spread on the required parts. The thickness of the material can be determined according to the design requirements of different furnace types.

2) Applicable area

Silicon carbide wear-resistant and refractory plastic can be widely used in cyclone separators, heat radiation materials and other parts where refractory materials are used. It has super strong bonding properties, and can be applied and rammed at any irregular wear parts, so that the degree of wear is greatly reduced, without the use of steel templates or molds. After the construction is completed, it can be ignited immediately without special maintenance, thereby shortening the construction period and saving costs.

3) Storage method

Avoid storage in the open air and prevent direct sunlight. In summer, it should be stored in a cool and humid place, and it should be protected from freezing in winter. The shelf life of plastics is generally 1 year, and the coagulant generally needs to be replaced if it is not used for 4-6 months (if it is used after 1 year of storage, it needs to be re-trapped).

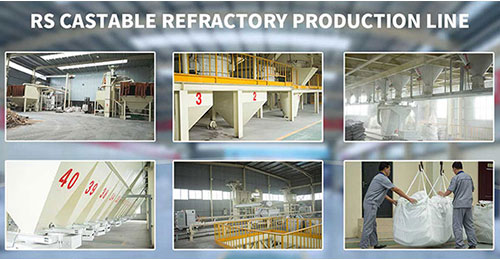

Rongsheng Refractories Materials Manufacturer

Unshaped refractory material, wear-resistant refractory plastic series, due to the different configuration of its raw materials, its inherent quality is different. For example, high alumina material, homogenizing material, and adding corundum or silicon carbide will have different grades, and there is also a big difference in price. When used, it depends on the temperature and wear-resistance of the used part. Rongsheng refractory material manufacturer has rich experience in the production and sales of refractory materials. Rongsheng’s refractory products have been sold to more than 80 countries around the world, such as Chile, Vietnam, Czech, Laos, Sri Lanka, Thailand, Portugal, Malaysia, Israel, Singapore, Tunisia, Indonesia, Bulgaria, Philippines, Kazakhstan, Turkey, Kuwait, South Africa, Egypt, Russia Uzbekistan, etc. Contact the refractory material manufacturer to obtain the configuration plan of the CFB boiler refractory lining material, and obtain free quotations and samples.