Ceramic fiber module is a new type of refractory lining product in order to simplify and accelerate the kiln construction and improve the integrity of furnace lining. It is white in color and regular in size, and can be directly fixed on the steel anchor nail of the industrial furnace shell. Ceramic fiber module has good refractory and heat insulating effect that can improve the integrity of the refractory insulation of the kiln and promote the improvement of the furnace masonry technology. What’s more, ceramic fiber module is widely used in the petrochemical, metallurgy, ceramics, and glass industries. So if you have any needs or requirements about ceramic fiber module, Contact us for more details!

The Features of Ceramic Fiber Module

Ceramic fiber module is made of ceramic fiber blanket through superimposed and cutting,whose shape is flat and no fiber breakage caused by unfolding, which has the advantage of higher anti-airflow scour. Ceramic fiber module uses the advanced RX2 anchorage system, all of which are installed outside the module and are quick and easy to achieve the most efficient installation and construction. The features of ceramic fiber module are as follows:

- Low Thermal Conductivity and High Energy-saving Effect. Ceramic Fiber Modules have a low thermal conductivity, which results in high energy savings.

- Low Heat Capacity.

- Good Chemical Stability.

- Good Thermal Shock Resistance. Ceramic fiber modules can withstand rapid thermal quench and temperature rise within the normal working temperature.

- Excellent Thermal Insulation. Ceramic fiber modules provide a good barrier to heat conduction and heat radiation, allowing for good insulation performance.

- Excellent Thermal Stability.

- Easy Installation. Ceramic fiber modules have easy and straightforward installation, allowing for short construction period.

- Lightweight.

- High Mechanical Shock Strength. Ceramic fiber modules are flexible and highly elastic.

- Ceramic fiber modules are not easily damaged by vibration and impact, which allows for less damage during shipping and installation.

Ceramic Fiber Module Applications

As a furnace lining insulation material, ceramic fiber modules can be widely applied in the petrochemical industry, metallurgical industry, building materials industry(such as ceramics and glass industry), heat treatment industry and other industrial furnaces. The typical uses of ceramic fiber module are as follows:

Ceramic fiber module for ceramic industry

- Low mass kiln cars

- Continuous and batch kilns

- Door linings

- Glazing, porcelain furnace linings

Ceramic fiber module for power generation

- Duct lining

- Heat recovery

- Steam system

- Boiler insulation

- Stack linings

Ceramic fiber module for steel industry

- Ladle pre-heaters and covers

- Heat treat furnace

- Soaking pit covers and seals

- Heaters and reformer lining

Ceramic fiber module for other applications

- Incineration equipment

- Burner blocks

- Induction furnace covers

- Glass tempering furnace

Ceramic Fiber Module Classification

Ceramic fiber modules can be classified into folding blocks, slice blocks, Paro blocks, vacuum forming blocks according to different molding methods.

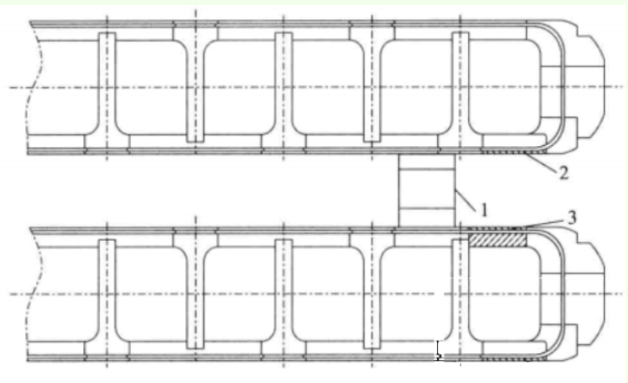

Folding block is one of the most widely used modular forms. The structure is folded using a needle blanket and the module is pre-pressurized using mechanical equipment during molding. Due to the uneven surface caused by the folding block making method, the effect of anti-scouring coating is affected, so the slicing block is produced.

The manufacturing process of slicing block is the same as the folding block, except that the fiber blanket is cut to make the module surface smooth after forming.

The Paro block is a brand-new module, whose module fiber after forming has no directionality. The forming method is completely different from the above two modules, so the thermal insulation effect of it is better than the first two modules.

{Advise:Top fiber module density had better be selected 230kg/m3, side wall fiber module density had better be selected 220kg/m3}

The classification temperature of ceramic fiber modules is between 1050℃ and 1400℃. So ceramic fiber module can be divided into the following types according to the temperature grade:

- 1050 Common Ceramic Fiber Module

- 1260 Standard Ceramic Fiber Module

- 1260 High Purity Ceramic Fiber Module

- 1400 High Alumina Ceramic Fiber Module

- 1400 Low Zircon Ceramic Fiber Module

- 1400 Zircon Ceramic Fiber Module

Ceramic Fiber Module Specification

| Classification Temperature Theoretical Density |

Ceramic Fiber Module 2300°F (1260℃) |

Ceramic Fiber Module 2600°F (1427℃) |

| In Stock Sized | 12 x 12 x 6 in 12 x 12 x 8 in 12 x 12 x 10 in |

12 x 12 x 6 in 12 x 12 x 8 in 12 x 12 x 10 in 12 x 12 x 12 in |

| Theoretical Density | 12.5 – 13.7 (lb/ft³) 200 – 220 (kg/m³) |

12.5 – 13.7 (lb/ft³) 200 – 220 (kg/m³) |

| Shrinkage on heating (%) | 1000℃ X 24H <= -3 | 1350℃ X 24H <= -3 |

Ceramic Fiber Module Installation Procedure

The installation procedure of ceramic fiber module is mainly including the following steps:

- Rust removal. Before construction, it is necessary to derust the copper plate of the furnace wall to meet the welding requirements.

- Wiring. According to the layout position of the ceramic fiber module shown on the design drawing, put the wire on the furnace wall board, and then mark the arrangement position of the anchor bolts at the welding point.

- Welding bolt. The bolts are welded to the furnace wall according to the welding requirements.

- Brushing high temperature coating.

- Tile blanket installation.

- Module installation.

- Compensation blanket installation.

- Furnace lining

- Furnace lining surface spraying.

- Flattening.

Ceramic Fiber Module Manufacturer

Ceramic fiber module for sale in RS company is famous for cheap price with the best quality all over the world. We RS factory not only have senior construction teams, but also logistics distribution, rapid delivery, and greatly shorten the transportation cycle. So everyone who is in need of ceramic finer module, Contact us right away! We will definitely provide you with efficient and satisfactory service.