Corundum Brick for sale from Rongsheng Refractory Company is a kind of kiln refractory bricks, which is widely used to build the lining of petrochemical thermal equipment under the condition of high temperature, high pressure, chemical erosion and mechanical wear. If you need to buy high quality corundum brick, just contact us for price through email.

What Is Corundum Brick

Corundum brick, also called corundum fire brick and corundum refractory bricks, is the corundum material with more than 90% Al2O3 content, choosing crystalline as the main phase. The high pressure strength of corundum brick at normal temperature is up to 340MPa. And the high load softening start temperature is above 1700℃. Corundum brick has good chemical stability, strong resistance to acid or alkaline slag, metal and glass liquid. The thermal shock stability is related to its microstructure. The corrosion resistance of the dense products is good, but the thermal shock stability is poor.

Corundum Brick Uses

- Used as abrasive tools for grinding high tensile metals, such as all kinds of common steel, malleable iron, hard bronze, etc.

- Used as advanced refractories and abrasives.

- Used as precision casting sand, spray coating, chemical catalyst, special ceramics.

- Used in the grinding process of dry grinding and deformable burn workpiece grinding.

- Used in the cracking of petrochemical and chemical fertilizers.

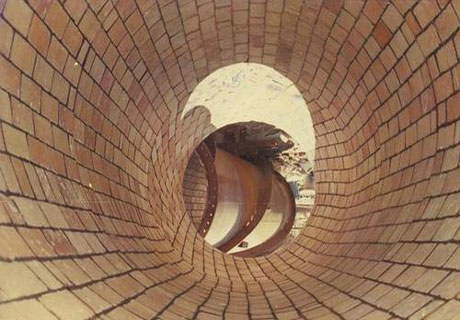

- Used in various high temperature kiln lining, like in reforming furnace and metallurgical industry.

All in all, corundum brick is used for blast furnace and blast furnace hot blast stove, steel refining furnace, sliding water heater, glass furnace and petrochemical industrial furnace.

Ingredients Of Corundum Brick

- Aluminum oxide

- Zircon sand

- Zirconium rich sand

- Sodium carbonate

- Borax

Properties of Corundum Brick

- Refractoriness under load is higher than 1700℃.

- High cold crushing strength up to 340Mpa.

- Good chemical stability.

- Good resistance to acid slag.

- Good resistance to alkaline slag.

- Poor thermal stability.

Classification Of Corundum Brick

- According To The Firing Mold

- Sintered corundum brick

- Electrofusion corundum brick

- According To The Material Component

- Brown corundum brick

Brown corundum brick is made of the raw material bauxite, coke (anthracite) , and is smelted at 2000 degrees inside the electric arc furnace. - White corundum brick

White corundum brick or white alundum is consisted of alumina powder after melting by high temperature. - High alumina corundum brick

High alumina corundum brick uses high quality bauxite as main materials and is smelted by special technology in high temperature electric arc furnace at 2500 degree. - Fused zirconia corundum brick

Fused zirconia corundum brick, also known as AZS, is arranged in sequence according to the three chemical components of the Al2O3-ZrO2-SiO2 three phase diagram. AZS is the short of Al2O3-ZrO2-SiO2: A represents Al2O3, Z represents ZrO2, S represents Si2O. - Single crystal corundum brick

Single crystal corundum is made by the major material bauxite and a small mount of sulphide, melting at high temperature. - Microcrystalline corundum brick

Microcrystalline corundum brick chooses bauxite as the raw material and is obtained by high temperature melting and extremely cold crystallization. -

Corundum Brick From RS

Index Of Corundum Brick

| Al2O3 % | Fe2O3 % | Apparent porosity % | Bulk density g/cm³ | Cold crushing strength MPa | RUL (0.2Mpa)

℃ |

Reheating linear change % | |

| CMC | ≥85 | ≤0.5 | ≤20 | ≥2.8 | ≥40 | ≥1500 | – |

| C90 | ≥90 | ≤0.8 | ≤20 | ≥3.0 | ≥80 | ≥1700 | 1550℃, 2h

±0.1 |

| C95 | ≥95 | ≤0.6 | ≤20 | ≥3.05 | ≥80 | ≥1700 | 1550℃, 2h

±0.1 |

| C98 | ≥98 | ≤0.4 | ≤20 | ≥3.1 | ≥80 | ≥1700 | 1600℃, 2h

±0.1 |

Cheap Corundum Brick For Sale In RS Factory! Click For Price!

Corundum Brick Manufacturing Process

The fused zirconia corundum brick for sale from Rongsheng Refractory is a white solid material formed with pure aluminum oxide powder and zirconium oxide containing 65% zirconia and zircon sand with about 34% silicon dioxide in the melting furnace. Its lithofacies are composed of the donor and glass phases of corundum and zirconium cable-stayed stone. From the point of view, the crystalline phase of the corundum and zirconium clinopyclite phase is filled with their crystallization.

Fused zirconia corundum bricks are made by melting and pouring raw materials into moulds, cooling and solidifying. Shrinkage cavity caused by volume shrinkage in the process of product condensation is something that should be paid special attention to when it is used.The electrofused zirconium corundum brick is cast by normal casting, inclined casting, no shrinkage cavity casting and quasi shrinkage cavity casting.

Corundum Brick Price

Different from other kiln refractory bricks, Corundum brick has good chemical stability and strong resistance to acid and basic slag. Why you choose corundum refractory bricks for your project, because corundum bricks have stronger performance in resisting fire and high temperature. And the corundum brick price is different from other common refractory bricks. According to the different components and structurers,corundum brick price will be different. You should know well about your requirements and choose the suitable corundum bricks for your furnace project. If you want to know more information about corundum brick price, you can contact Rongsheng Refractory Company for consultation.

Corundum Brick Manufacturer

Rongsheng Kiln Refractory Company is one of professional corundum brick manufacturers and suppliers in China, which can provide the customers with high quality corundum refractory bricks and best service. Rongsheng strictly controls the quality of corundum brick products and offers the best after-sales service with sincerity and earnest. Any need of Cheap Corundum Brick? Come and find Rongsheng corundum brick manufacturer! Just email us to get the best corundum brick price!